Collection: Commercial Heat Sealer Machines

Heat Sealer Machines For Medical, Industrial & Manufacturing

Heat sealer machines, also known as bag sealers, are devices used to seal various types of packaging and thermoplastic materials. There are different designs for different sealing work requirements, including sealing to certain Clean Room standards.

Here at Valdamark, we provide a complete range of high-quality commercial heat sealers for all purposes, including dedicated pouch sealers, sealers with cutters and hand-held heat sealers.

Whether you’re looking for industrial sealers, medical heat sealers or commercial sealers, you’ve come to the right place. If you’re not sure which of our high-quality heat sealer machines is right for you, don’t hesitate to get in touch today.

Choose The Right Heat Sealer Machine For You

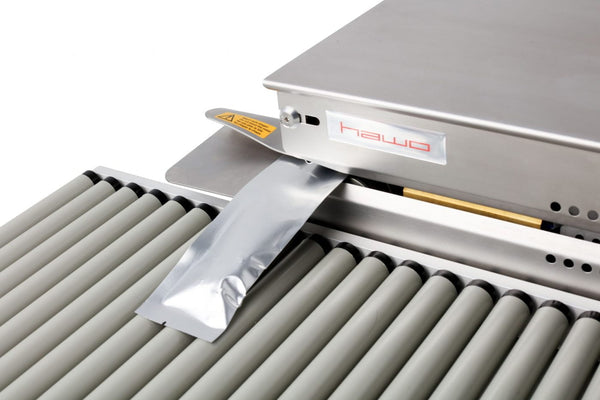

At Valdamark, we provide only the most reliable, hard-wearing and effective heat sealers on the market. We partner with the world’s leading brands, including Hawo to deliver specialist heat sealers suited for a variety of industries. Whether you’re looking for an impulse heat sealer, constant heat sealers or industrial heat sealers to meet manufacturing or medical standards, we offer a diverse range of stock to suit your needs.

Browse Our Wide Range of Heat Sealing Machines

Search through our diverse heat sealer solutions today. If you’re struggling to identify the right solution for your business, don’t hesitate to email us directly. Our friendly sales team make sure all our customers receive the right heat sealing machines for their needs. Whether you’re looking for specialist medical sealers, an impulse heat sealer or the latest in commercial heat sealing technology, don’t hesitate to get in touch today. All our machines are guaranteed to deliver a heavy duty seal on your medical or product packaging, ensuring complete control over the quality and protection of the product.

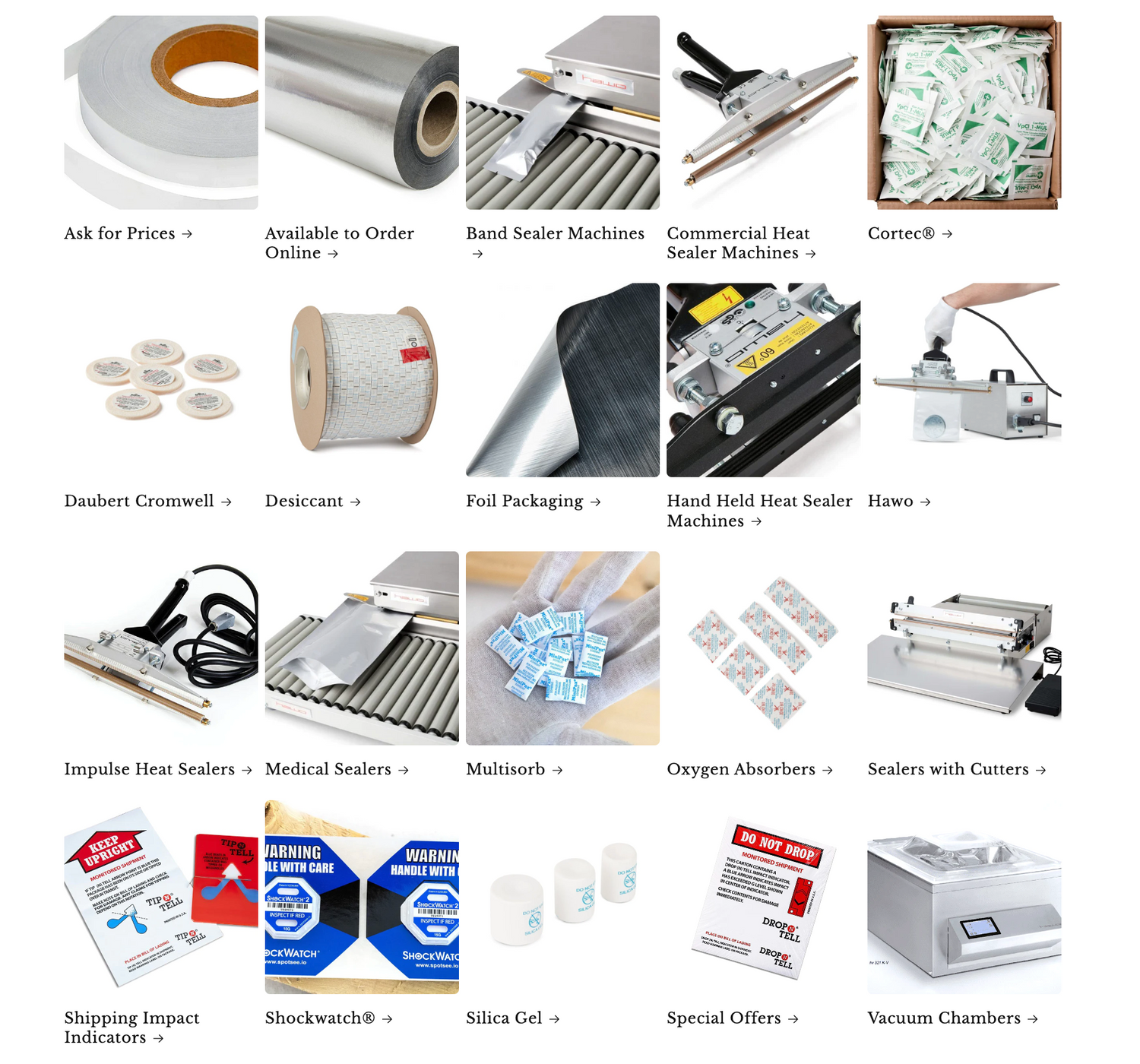

Our Complete Range of Heat Sealer Machines

If you’re looking for high-quality heat sealers, you’ve come to the right place. We can provide a complete range of bag sealers, impulse sealers and industrial heat sealers offering a cost-effective solutions for businesses, medical processes and industrial manufacturing packaging and more.

Here at Valdamark, we can provide a diverse variety of heat sealers, to create a cost-effective solution for your business. We deliver high-quality machines, suitable for sealing industrial and medical stock, in addition to adhering to ISO 14644-1 Clean Room Standards.

Which Heat Sealer?

Heat sealing machines and bag sealers come in a variety of styles to suit your needs. Whether you’re looking for impulse heat sealers, constant sealers or table-top sealers with cutters, Valdamark provides a complete range of reliable and user-friendly machines, which are ideal for industrial manufacturing and medical purposes.

If you’re struggling to find the right sealing machine to suit your manufacturing, commercial or industrial needs, get in touch today. We are more than happy to offer advice and support to make sure you choose the right heat sealing machines for your business and industry.

Common Heat Sealer Machine Questions

|

What Are Commercial Heat Sealers Used For? A heat sealer is an essential machine for many businesses, which uses specialised heating elements to bond two materials together. This process is often used in order to seal food and food products, medical products and even as part of the manufacture process for sensitive equipment and tools. If you’re not sure which is the right sealer for you, search our wide range today. At Valdamark, we can provide a complete range of industrial heat sealers, in addition to impulse sealer machines which are suitable for less-intensive commercial use. |

|

Can Heat Sealers Be Used With Cardboard Boxes? No, heat sealing machines are not suitable for use with cardboard boxes, or any non-approved packaging. Our hard-wearing machines can use a wide range of polythene packaging materials, and other approved materials, but no cardboard boxes. Our commercial sealers are designed for use in medical and industrial environments, ensuring that your packaging meets all appropriate cleanroom standards. They are also suitable for a wide range of product packaging, but if you’re unsure whether our commercial models are right for you, don’t hesitate to get in touch today. |

|

Do Heat Sealing Machines Use Approx Size? Heat sealing machines are adaptable, and can often be used to seal bags, pouches and other materials of various sizes. Some machines can use layflat tubing to customise your own bag sizes as part of the heat sealing process. Not all heat sealers are suitable for use with layflat tubing, so please check with our friendly support team before adding to your basket. |

|

What's The Difference Between A Heat Sealers & Vacuum Sealers? Whereas heat sealers are designed to seal using intense heat, vacuum sealers remove all the air from the bag, then seal it. Vacuum sealers are often used in medical and food industries to prevent any kind of damage or degradation, typically caused by humidity, moisture or exposure to air. At Valdamark, we can provide both vacuum and heat sealers which are suitable for commercial, industrial and medical environments. |

|

What Materials Can I Seal? Many sealers can seal different types of materials, but it is important remember that some are not suitable for certain materials and different thicknesses. Our range of commercial sealers are market leading and will seal the majority of flexible packaging materials and constructions. The best way to be certain is to send us a sample for testing.

|

|

What Is The Best Way To Determine Which Heat Sealer I Need? If you are unsure which commercial sealer is most suitable for your project we recommend that you send a sample pouch or piece of material for testing. In addition if you have any more information like a packaging specification this is always helpful, most manufacturers will advise on the approximate temperatures for the sealing of each film. It provides us with a good starting point in order to conduct some sealing tests. If you prefer you can do this yourself once you receive the machine. Generally we recommend that you start off with a seal time of 2 – 3 seconds at 150 degrees Celsius. Then let the seal cool for 2x or 3x the heat time. This should give you a good indication of whether to increase or decrease the temperature & sealing time. |

|

What Are Hand Held Heat Sealers? Hand Held Heat Sealers are a speciality for Valdamark. These are machines we use in our own hand fabrication and production facilities. We know and trust them as the best available for professional heat sealing. Our current range are all lightweight, easy to use machines that create optimal seals consistently and with ease. This is essential when doing mid to high volume sealing work as the operator will require a reliable machine that is lightweight to avoid handling fatigue. Most importantly of all though is that the machine is safe to use! In our experience most of the commercial hand heat sealing machine models on the market are unsuitable for repeat or high volume sealing. All our machines are approved to the CE standard as well as being built in accordance with the GS standard for electrical work. Each comes complete with a 2 years manufacturers warranty. |

|

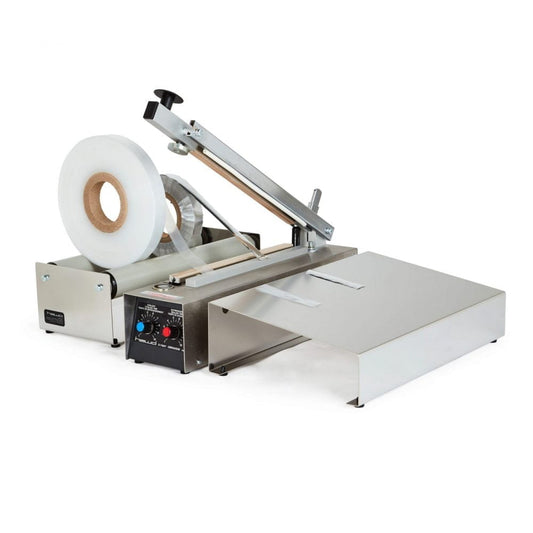

Does Valdamark Offer Foot-Operated Bag Sealer Machines? Yes, we do! Our HPL range are all foot operated impulse sealers as standard. A foot pedal allows the operator to complete the seal cycle ‘hands free’ whilst safely allowing them to concentrate on positioning the packaging correctly. It is a faster process as well. The HPL is a professional machine that is perfect for use in medical and pharmaceutical packaging environments. Well suited to the sealing of sterile barrier packaging films it can be supplied as a stand alone machine or with a range of options including a work table and roll holder/ film unwinder. If you are looking for a standing sealer take a look at the V2A vertical stand and work table options for further improved efficiency. This food grade, stainless steel construction is a popular configuration where Good Manufacturing Practice (GMP) guidelines need to be adhered to. These products conform in full with the CE European Safety Standards and carry the GS standard for electrical and technical work. Sealing machines have different widths to suit the width of the seal you want to create. As a rule, choose a sealer that is between 20mm and 50mm wider than the width of your packaging. This just gives you more manoeuvrability as the packaging can easily be positioned without overlapping the edges of the machine. Our heat sealing machines start at 300mm width all the way up to 1000mm. These sizes will suit most projects but bespoke widths can be made to order. |

|

What Are Impulse Heat Sealers? Impulse heat sealing machines deliver heat in an impulse (or short interval). An impulse heat sealer uses a low voltage heating containing wires that have virtually no heat up time. This allows you to get up to your desired temperature and seal in seconds. The heating element then cools down but retains the pressure allowing the sealed material to set. This makes them economical to run as from a power perspective. Usually, an impulse heat sealer or bag sealer is used on packaging that contains identical thermos-plastic films on all sides. This is usually a polythene material but they can be used for thinner gauge laminate materials. |

|

What Is A Constant Heat Sealer? A constant heat sealer machine will deliver heat in just that way, constantly! More specifically this concept refers to a manual sealing machine whereby heat is applied for as long as the operator compresses the sealing bars. In other words you select the appropriate sealing temperature and clamp the seal for as long as is necessary for the material to weld! This is slightly different to an impulse sealer in that with an impulse machine the only setting is ‘on & off’. You cannot adjust the temperature usually. The seal time is pre-set by the operator. Usually between 1 & 10 seconds. Constant machines do seem to be slightly better suited for heavy duty bag sealing as you are able to take advantage of the higher temperature settings and also time each seal. This makes ideal for industrial bag sealing. The WSZ is very compatible with bulk bags, container liners, octabin packaging & gusset bags. It is worth considering though that modern impulse heat sealing machines such as the ISZ will match the performance of constant heat sealers in terms of seal quality and strength. |

|

What Is A Rotary Heat Sealer? Rotary foil bag sealers are usually used for laminated materials made up of multiple layers of thermoplastic film. These can have different mechanical properties and melting points depending on the construction. Laminate Foils, coated papers, cellulose films, cellophane and polypropylene films will often require a constant seal. Our devices all have temperature controllers to keep the seal bars at the desired and precise temperature. With constant sealing the inner layer is sealed without any defect to the backing material. |

|

What Is Crimping? The word crimp refers to the serrated seal pattern on some packaging machines. Its primarily there to improve seal strength and avoid de lamination of any multi layered materials. This id often referred to as the crisp bag sealer. Or crimp heat sealer. It’s the client’s personal preference to have this or not. |

|

Do I Need A Heat Sealer With A Cutter, Or Without? Industrial heat sealers with cutter knives are for those who wish to make their own custom sized bags from film on a reel. Often with lay flat tubing or another polythene material. Here you just measure the material to size and cut off any excess by closing the jaw and sliding the easy to use cutter blade. At Valdamark, we can provide a complete range of industrial heat sealer machines, with and without cutting attachments. |

|

Which Are The Best Heat Sealers For Plastic Bags? As above it will depend on the material of your packaging, the environment and the volume of sealing you need to do. If you decide on a table top sealer, the HPL 300 BMS & HPL 500 BMS are excellent mid range options. These are impulse bar sealers that feature interlocking magnets to ensure perfect seals for every seal. Available in both 300mm & 500mm cutting lengths. A good choice for high volume sealing would be the HPL 450, 630 & 1000 AS machines. These commercial bag sealers are reliable, durable and utilise affordable consumable components which is perfect for ensuring longevity with regular maintenance and repairs. |

|

Does Valdamark Calibrate Any Of The Heat Sealers? Yes we do! We offer a simple and convenient calibration service for all our medical sealer machines. We understand that down time is an important consideration for clients who rely on their machine for production continuously. We are flexible in delivering our calibration service and can often do this on site when arranged prior. Whether you’re looking to seal polythene, or any other suitable sealing material, we can calibrate your machine to meet your exact standards. Our maintenance and calibration services are delivered in full compliance with BS EN 868-5 & ISO 11607-2. For audit assurance we issue a fully traceable certificate confirming seal strength and integrity. |

|

Does Valdamark Provide An After Sales Service And Replacement Parts? Yes. Valdamark supplies from stock a range of HAWO spare parts including those for the WSZ & ISZ models. Specifically, this includes the most commonly used consumable parts like PTFE (Teflon) strips as well the heating elements, thermostats and welding bands. Hawo Sealers have a warranty returns rate of less that 0.05% of total sales. In the unlikely event your heat sealer does fail get in touch with us first to discuss this. If troubleshooting indicates a defect we will happily take the heat sealer back under warranty. If you have any questions about the after-sale support that we offer, don’t hesitate to get in touch via our email address, or simple online contact form. |

-

Call for quote

Call for quoteHawo HM 460 AS-V & HM 660 AS-V Validatable Impulse Sealers

Regular price £0.00 GBPRegular priceUnit price / per£0.00 GBPSale price £0.00 GBPCall for quote -

Hawo HPL 1500 & 1800 Impulse Heat Sealer For The Production Of Pallet Covers

Regular price £0.00 GBPRegular priceUnit price / per -

Hawo HPL ISZ IVM 300mm, 250mm & 630mm Spare Parts Kit

Regular price £298.50 GBPRegular priceUnit price / per -

Hawo HPL WSZ/WVM 300 & 400mm Constant Heat Sealer Tongs (250 C) Hand Heat Sealing Machine

Regular price From £687.02 GBPRegular priceUnit price / per -

Hawo HPL ISZ IVM 300mm Hand Held Impulse Heat Sealer

Regular price From £784.31 GBPRegular priceUnit price / per -

Hawo HPL ISZ IVM 450mm Hand Held Impulse Heat Sealer

Regular price From £823.65 GBPRegular priceUnit price / per -

Hawo HPL 300 & 500 BMS Table Top Heat Sealer

Regular price From £825.00 GBPRegular priceUnit price / per -

Hawo HPL ISZ IVM 630mm Hand Held Impulse Heat Sealer

Regular price From £875.48 GBPRegular priceUnit price / per -

Hawo HPL 450, 630 & 1000 AS Bar Sealer Foot Operated Impulse Sealer

Regular price From £1,531.24 GBPRegular priceUnit price / per -

Hawo HPL 500 D-V & 3000 DC-V Rotary Heat Sealer

Regular price From £2,548.25 GBPRegular priceUnit price / per

Knowledge Base

View all-

Learning From Brands Like Ben & Jerry’s, Newman...

Marketing magic transforms brands into real-life superheroes. Whether they champion communities, empower diversity, or embrace eco-heroics, brands can inspire with captivating stories. Think underdog origins, brand-as-hero journeys, and authentic struggles...

Learning From Brands Like Ben & Jerry’s, Newman...

Marketing magic transforms brands into real-life superheroes. Whether they champion communities, empower diversity, or embrace eco-heroics, brands can inspire with captivating stories. Think underdog origins, brand-as-hero journeys, and authentic struggles...

-

Benefits of Sustainable Sourcing will be Promot...

PEFC, the Programme for the Endorsement of Forest Certification, will be a participant at the upcoming Packaging Innovations show in London on September 16th and 17th. The organization will showcase...

Benefits of Sustainable Sourcing will be Promot...

PEFC, the Programme for the Endorsement of Forest Certification, will be a participant at the upcoming Packaging Innovations show in London on September 16th and 17th. The organization will showcase...

-

Amcor Pouch Packaging Solution Addresses Drug D...

In the demanding world of medical and healthcare, ensuring the sterility and shelf life of combination medical devices is paramount. This requires high-performance, sophisticated packaging materials that act as effective...

Amcor Pouch Packaging Solution Addresses Drug D...

In the demanding world of medical and healthcare, ensuring the sterility and shelf life of combination medical devices is paramount. This requires high-performance, sophisticated packaging materials that act as effective...