BOBST innovations in COMPETENCE 15 Draws Over 300 Packaging Manufacturers

Alex ToddPackaging manufacturers COMPETENCE 15 – held from June 23 to June 25, saw the global première of several new BOBST developments.

This included a foil packaging Unwinder+, an innovative foiling solution that offers significant savings in foil use; EXPERTCODE, a new digital serialisation machine to meet the growing needs of packaging makers worldwide for customisation and coding; and VISIONCUT 106 LER, a highly productive, pioneering blank separating die-cutter.

NOVACUT 106 ER made its European debut in the event. This blank separating die-cutter is already giving customers around the world a very cost-effective entry into high quality in-line blanking.

BOBST Business Unit Sheet-fed’s Head of Sales – Emilio Corti, emphasised their commitment towards continuous innovation.

He said every new piece of equipment has been designed to improve the packaging manufacturers’ profitability in the commercial sector.

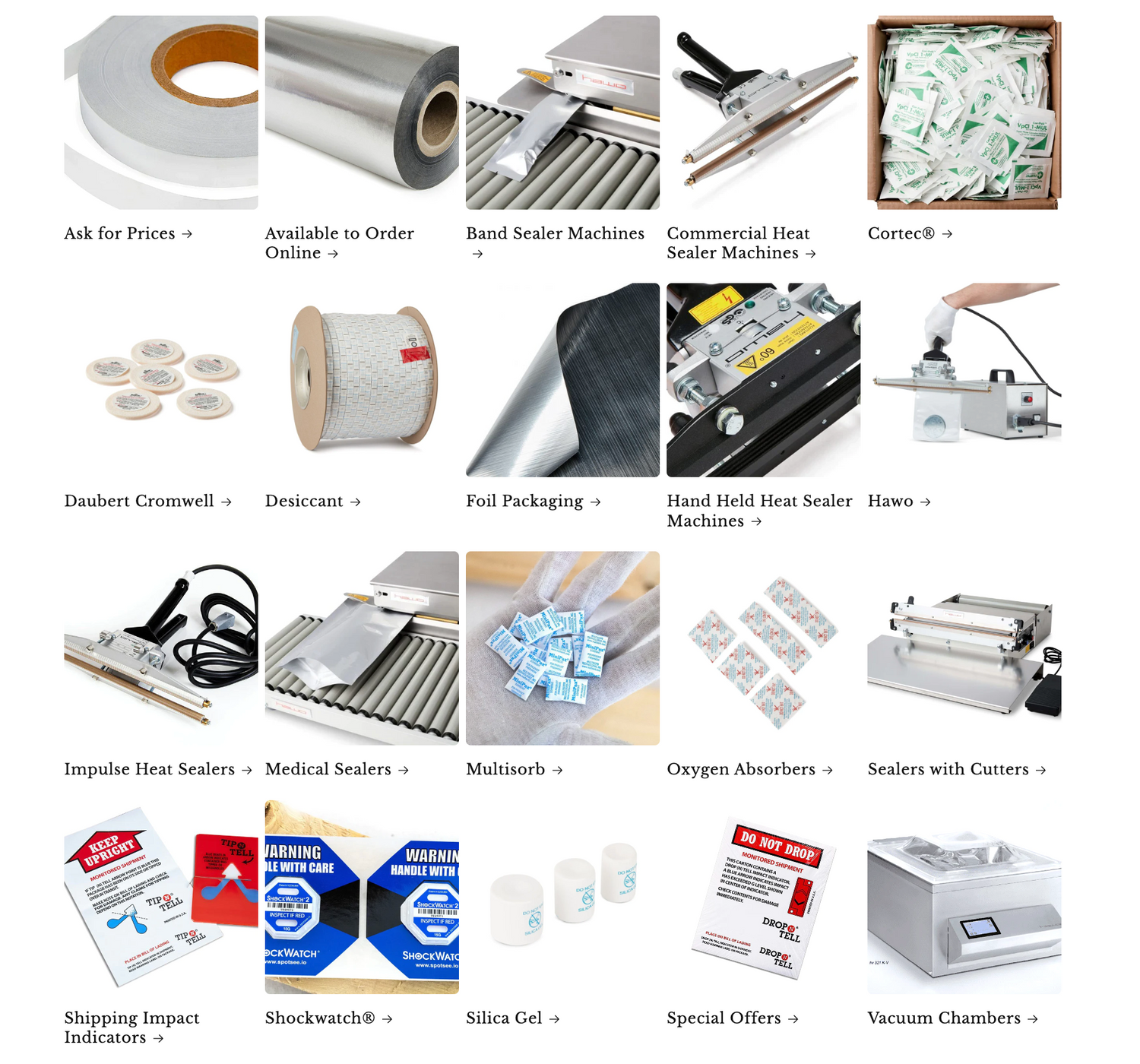

Systems, Equipment and services to Help Packaging Manufacturers

Several packaging manufacturers were interested in the Foil Unwinder+ that encourages foil use optimisation. It decreases foil consumption by as much as 50%, based on the job’s layout.

With VISIONCUT 106 LER, there’s no longer the requirement for the hand stripping of waste.

Thus, packaging manufacturers can improve product quality, decrease labor costs and increase productivity. With growing pressure on manufacturers to become more efficient, this new die-cutter is sure to help them.

NOVACUT 106 ER having BOBST Angle Lock blanking tool system integrated into it, complements the VISIONCUT. It gives carton makers all over the world a mode to access in-line blank separation technology.

EXPERTCODE – a digital printing initiative from BOBST, is a system that addresses anti-counterfeiting, traceability, versioning and customisation of packs.

With it, packaging manufacturers can digitally print individualised graphics, codes, texts, or off-line onto blanks or cartons that are already folded and glued.

The system allows manufacturers to do all these at high speed and with high resolution as well as immediate verification.

Some complementary conference programs also focused on various challenges faced by the packaging industry and ways to overcome them. BOBST’s Alex Volery did an evaluation of packaging trends in the cosmetics industry.

Steven Klump of Nestlé analysed the food safety challenges faced by digitally printed packaging. François Hosotte of Ferring talked about the secondary packaging challenges faced by pharma brand owners and their suppliers.

Nestlé’s Alvise Cavallari summarised how developments in digital printing offer several opportunities to the heat sealer industry.

BOBST Participates in K 2022

At K 2022, BOBST showcases its Connect platform, which aims to improve efficiency and quality across the value chain for converters and brand owners. Connect links different steps in the production process, giving users clear visibility and control over the process.

The platform also offers data analysis capabilities to help users improve quality and productivity. In addition, BOBST has developed a range of digital tools to help users automate their workflow and improve communication between different stakeholders. By offering a suite of connected solutions, BOBST is helping its customers to overcome challenges and drive growth in the global market.

BOBST Introduces PrimeCycle

Although metallised polyester film has been the go-to material for barrier packaging in the past, its reliance on EVOH and top-coatings makes it difficult to recycle. BOBST’s oneBARRIER PrimeCycle offers a sustainable alternative that is just as effective at preserving product freshness. As a polymer-based mono-material, oneBARRIER PrimeCycle can be easily recycled without compromising its barrier properties.

This makes it a potentially groundbreaking development for the packaging industry, which is under increasing pressure to reduce its environmental impact. With its strong commitment to sustainability, BOBST is leading the way in finding innovative solutions that will help to preserve our planet for future generations.

BOBST Partners with the PrimeCycle

BOBST is committed to driving sustainability in the packaging sector and has been working on the oneBARRIER PrimeCycle initiative for a number of years. This ground-breaking project aims to create a new model for recycling flexible packaging. This currently has a low recycling rate due to the multi-layer construction of most packaging materials.

The oneBARRIER PrimeCycle project involves a number of partners, each of whom brings their own expertise to the table. For example, Dow is providing their innovative recyclable barrier film, while Michelman is supplying their water-based barrier coatings. Sun Chemical will be responsible for supplying inks and other printing consumables, while Zermatt will be providing their cutting-edge recycling technology.

These partners will all be present at K 2022 to demonstrate their vital contributions to this exciting development. BOBST is also working with a number of other packaging manufacturers as partners on the overall oneBARRIER initiative. This partnership is aimed at developing sustainable solutions for the flexible packaging sector.

Sustainability Commitment of Packaging Manufacturers

Aside from the oneBarrier, this packaging manufacturers has also joined a strategic partnership with Evertis, barrier film expert company and BASF, adhesives specialist. These three are helping Sulayr, a recycling company in creating a loop cycle for PET based laminates.

For more news related to product packaging systems, equipment and services, visit the site.