Daubert Cromwell Premium MetalGuard® VCI Gusseted Poly Bags | Various Sizes & Volumes

Daubert Cromwell Premium MetalGuard® VCI Gusseted Poly Bags | Various Sizes & Volumes

120 in stock

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Protect Your Metal Parts During Storage and Transport with Daubert Cromwell MetalGuard® VCI Gusseted Bags

Daubert Cromwell MetalGuard® Gusset Bags are the ideal solution for protecting your valuable metal parts from rust and corrosion during storage and transport. Here's why they stand out:

Environmentally Friendly Choice:

- MetalGuard® Gusset Bags are a much greener alternative to traditional rust prevention methods like oils and desiccants. These older methods can be messy, hazardous, and difficult to dispose of responsibly.

- Daubert Cromwell's innovative technology utilises a "best-in-class" Volatile Corrosion Inhibitor (VCI) embedded directly into the bag material. This eliminates the need for additional chemicals, reducing your environmental impact.

Superior Metal Protection:

- The VCI formula within the gusset bags vaporises upon sealing, creating an invisible protective layer on your metal parts. This layer is effective against a wide range of threats, including salt water, sea air, moisture, and even gas products.

- MetalGuard® Gusset Bags are compatible with a variety of metals and alloys, including mild steel, cast iron, stainless steel, galvanised steel, copper, brass, bronze, zinc, tin, and even silver. This makes them a versatile solution for a wide range of applications.

Convenience and Cost-Effectiveness:

- Daubert Cromwell offers MetalGuard® Gusset Bags in various pre-made sizes to suit your specific needs. This eliminates the need for custom cutting and ensures a proper fit for your parts.

- The bags are ready to use straight out of the box. Simply place your clean and dry metal parts inside and seal the bag. No additional chemicals or complicated procedures are required.

- MetalGuard® Gusset Bags are also very economical. They are available in stock for quick delivery, saving you time and money.

Please select the ► play button on the video below

Long-lasting Protection:

- The VCI layer formed within the bag offers extended corrosion protection for your metal parts. It typically forms within 24 hours under normal ambient conditions, providing peace of mind during storage and transport.

- The protective layer can even regenerate to a certain extent, allowing you to briefly open the bag to inspect your parts without compromising its effectiveness.

Additional Benefits:

- MetalGuard® Gusset Bags are made from a superior strength, flexible VCI film, offering reliable protection for your parts.

- The film is also heat sealable, ensuring a secure closure and optimal VCI performance.

- These bags are free of nitrates, making them a safe choice for your workers and the environment.

- By choosing Daubert Cromwell MetalGuard® Gusset Bags, you can ensure your metal parts arrive at their destination in pristine condition. With their eco-friendly design, superior protection, and convenient use, these bags are the perfect solution for all your metal storage and transportation needs.

Sizes:

- Gusset Bags - 200 x 500mm (500 Pieces Per Box).

- Gusset Bags - 320 x 600mm (250 Pieces Per Box).

- Gusset Bags - 400 x 800mm (100 Pieces Per Box).

- Gusset Bags - 650 x 1350mm (100 Pieces Per Box).

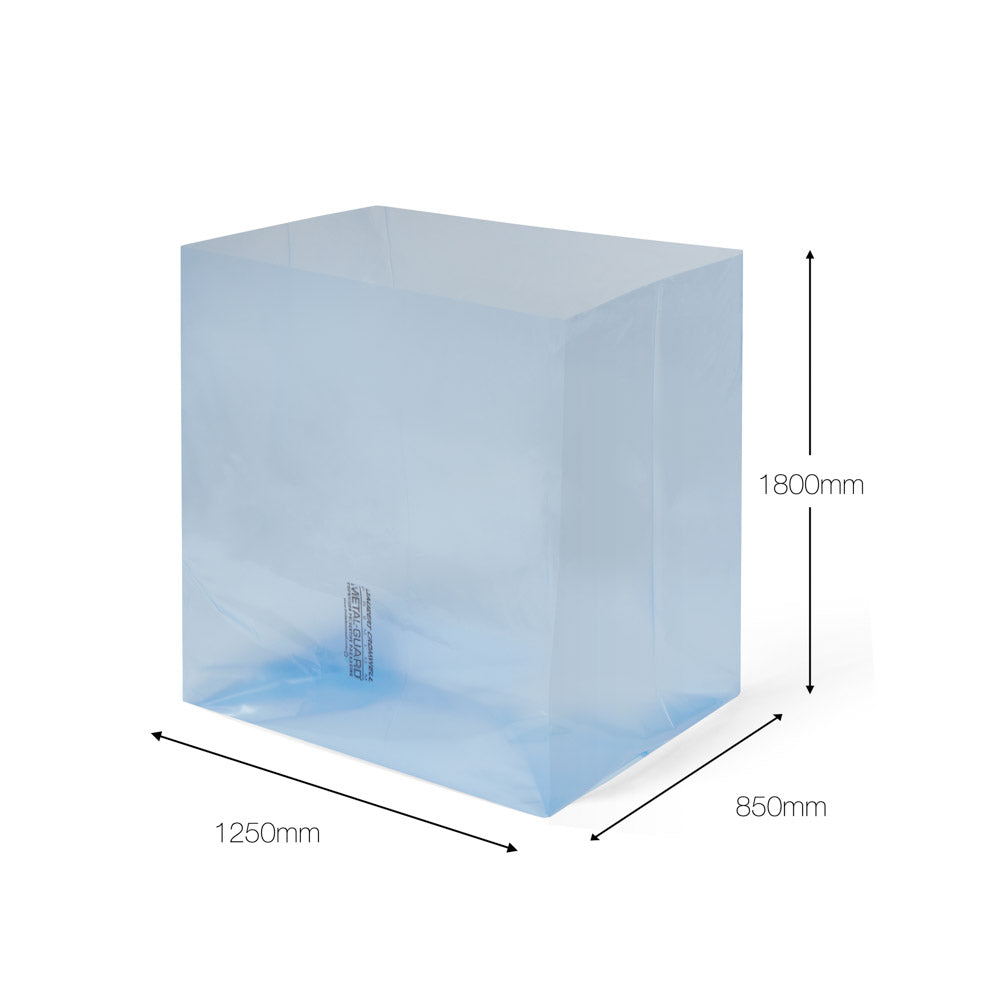

- Gusset Bags - 850 x 1800mm (35 Pieces Per Roll).

Delivery Time

2 – 3 working days.

Product Specifications (.PDF)

Frequently Asked Questions

• What are Daubert Cromwell MetalGuard VCI Gusseted Bags and how do they prevent rust?

Daubert Cromwell MetalGuard VCI Gusseted Bags are innovative packaging solutions made from a superior strength, flexible VCI (Volatile Corrosion Inhibitor) film. These bags work by releasing a special VCI formula that vaporizes within the sealed bag, forming an invisible, molecular protective layer on the surface of your metal parts. This protective layer actively prevents rust and corrosion by blocking the electrochemical reactions that cause degradation, ensuring your items remain pristine.

• What makes the "VCI" technology in these bags so effective for corrosion protection?

The VCI technology in Daubert Cromwell MetalGuard bags is exceptionally effective because it operates in both vapor and contact phases. The VCI molecules not only protect surfaces they physically touch but also vaporize to reach all exposed and even hard-to-reach internal surfaces, like those within complex machinery parts. This comprehensive coverage creates a full protective atmosphere inside the bag, shielding against moisture, salt, sea air, and other corrosive elements.

• Are Daubert Cromwell MetalGuard VCI Gusseted Bags a sustainable packaging choice?

Yes, these bags are indeed a more environmentally friendly option compared to traditional rust prevention methods like messy oils and desiccants. They eliminate the need for additional chemicals, are free of nitrates, and are recyclable, reducing your environmental footprint and making disposal much simpler and more responsible.

• What types of metals can I confidently protect with Daubert Cromwell MetalGuard VCI Gusseted Bags?

Daubert Cromwell MetalGuard VCI Gusseted Bags are remarkably versatile, providing excellent protection for a wide array of metals and alloys. This includes mild steel, cast iron, stainless steel, galvanized steel, copper, brass, bronze, zinc, tin, and even silver, making them a comprehensive solution for diverse metallic components.

• How long can I expect metal parts to be protected when stored in Daubert Cromwell MetalGuard VCI Gusseted Bags?

When properly sealed and used for indoor storage, Daubert Cromwell MetalGuard VCI Gusseted Bags offer extended, long-term corrosion protection. The protective VCI layer typically forms within 24 hours under normal ambient conditions and can provide protection for up to 24 months or even longer, depending on the storage conditions.

Relevant products you may want to consider:

• What's the best way to prepare my metal parts before placing them into a Daubert Cromwell MetalGuard VCI Gusseted Bag?

For optimal results, ensure your metal parts are clean and dry before packaging. It's also recommended that packaging personnel wear gloves while handling bare metal parts to prevent fingerprints or oils from interfering with the VCI protection.

• How do I properly seal a Daubert Cromwell MetalGuard VCI Gusseted Bag to ensure maximum protection?

These gusseted bags are heat sealable, meaning you can achieve a secure and airtight closure using a poly hand sealer. A recommended setting is typically 2 seconds at 180°C (356°F) to ensure the VCI vapors are effectively contained within the bag, maximizing protection.

• Can Daubert Cromwell MetalGuard VCI Gusseted Bags be used to cover large, oddly shaped items or pallets?

Absolutely! The gusseted design of these bags allows them to expand, making them ideal for covering large, bulky, or irregularly shaped items, pallets, and even for lining crates, gaylords, and boxes, providing comprehensive protection for your substantial components.

• Is it possible to open and reseal these VCI bags without compromising the corrosion protection?

Yes, one of the convenient features of Daubert Cromwell MetalGuard VCI Gusseted Bags is that the VCI layer can regenerate to a certain extent. This means you can briefly open the bag to inspect your parts without significantly compromising the long-term effectiveness of the corrosion protection, though it's always best to reseal them quickly.

• How close should the metal part be to the VCI film for the best corrosion protection?

For optimal effectiveness, the metal part should be placed no more than 12 inches (30 cm) from the Daubert Cromwell MetalGuard VCI film. The closer the proximity, the more efficiently the VCI molecules can condense and form their protective layer on the metal surface.

Relevant products you may want to consider:

• Can these bags be used for overseas shipments, or are they only for indoor storage?

Daubert Cromwell MetalGuard VCI Gusseted Bags are designed for robust long-term protection, making them perfectly suitable for rigorous conditions encountered during overseas shipments, as well as for prolonged indoor storage. They provide a reliable barrier against the various corrosive elements present during transit.

• Are there any specific "don'ts" when using Daubert Cromwell MetalGuard VCI Gusseted Bags?

Yes, there are a few important points: Do not leave unused bags or packaged items open, always close and seal them properly. Also, avoid having metal parts directly touch acidic packing materials like cardboard boxes or wooden pallets unless a VCI barrier is placed in between, as this can lead to corrosion at contact points.

• For what specific industries are Daubert Cromwell MetalGuard VCI Gusseted Bags particularly well-suited?

These bags are highly valued across a multitude of industries, including automotive, heavy equipment, electronics, military, steel manufacturing, and general metal fabrication, offering reliable corrosion protection for a wide range of components within these sectors.

• Can I use Daubert Cromwell MetalGuard VCI Gusseted Bags to protect engine components or large machinery parts?

Absolutely! Due to their gusseted design and robust VCI protection, these bags are an excellent choice for wrapping and protecting larger items such as engine blocks, camshafts, crankshafts, bearings, and other substantial machinery parts during storage or transport.

• Will these bags protect sensitive electronic components from corrosion?

While the primary focus is on metal corrosion, the VCI technology does provide a clean, dry, and effective barrier against environmental factors that could impact sensitive components. For electronics, ensuring full compatibility with specific materials is always advisable.

Relevant products you may want to consider:

• How do these bags assist in streamlining the packaging process?

Daubert Cromwell MetalGuard VCI Gusseted Bags are ready to use straight out of the box, eliminating the need for messy oils, greases, or additional chemical applications. This "clean and dry" packaging approach significantly reduces processing time, labor, and the need for post-storage cleaning, saving both time and money.

• Do Daubert Cromwell MetalGuard VCI Gusseted Bags offer protection against physical damage in addition to corrosion?

While their primary function is corrosion inhibition, the superior strength and flexible VCI film of Daubert Cromwell MetalGuard bags also provide a physical barrier that helps protect parts from dust, debris, and minor abrasions during handling and transport. For impact protection, additional cushioning may be needed.

• Can these bags help reduce rework or cleaning processes after storage?

Yes, significantly. Because the VCI protection keeps metal parts clean, dry, and rust-free, items emerge from the bags ready for immediate use, assembly, or further processing without the need for additional cleaning, degreasing, or rework, which is a major cost and time saver.

• Are Daubert Cromwell MetalGuard VCI Gusseted Bags transparent, allowing for easy content identification?

Yes, they are typically made from a transparent VCI film, which allows for visual inspection of the packaged parts without needing to open the bag, improving inventory management and efficiency. They are usually tinted a specific "Daubert blue" for easy identification as a quality VCI product.

• What is the typical film thickness of Daubert Cromwell MetalGuard VCI Gusseted Bags?

While variations exist, Daubert Cromwell MetalGuard VCI Gusseted Bags are commonly supplied in a 4 mil (100µm) thickness, providing excellent strength, tear resistance, and barrier properties for reliable protection.

Relevant products you may want to consider:

• Are these bags free of nitrates? Why is that important?

Yes, Daubert Cromwell MetalGuard VCI Gusseted Bags are proudly free of nitrates. This is important because nitrates can be harmful to both workers and the environment, and their absence makes these bags a safer and more compliant choice for various industries.

• Do Daubert Cromwell MetalGuard VCI Gusseted Bags meet any specific industry standards or approvals?

Yes, Daubert Cromwell MetalGuard VCI film, including the gusseted bags, is typically approved to stringent industry standards like TL 8135-0043, Level 3, demonstrating their high level of performance and reliability in demanding applications.

• Are these VCI bags recyclable?

Yes, Daubert Cromwell MetalGuard VCI Gusseted Bags are designed to be recyclable, contributing to more sustainable waste management practices within your operations.

• What are the common sizes available for Daubert Cromwell MetalGuard VCI Gusseted Bags from Valdamark Direct?

Valdamark Direct typically stocks Daubert Cromwell MetalGuard VCI Gusseted Bags in a range of common sizes to accommodate various part dimensions, such as 200 x 500mm, 320 x 600mm, 400 x 800mm, 650 x 1350mm, and even larger sizes like 850 x 1800mm, often supplied on rolls for convenience.

• Is there a recommended storage temperature or condition for unused Daubert Cromwell MetalGuard VCI Gusseted Bags?

To maintain their optimal effectiveness, it is recommended to store unused Daubert Cromwell MetalGuard VCI Gusseted Bags in a cool, dry area, away from direct sunlight, and not in high humidity or temperatures exceeding 80°F (27°C).

Relevant products you may want to consider:

• How quickly can I typically receive an order of Daubert Cromwell MetalGuard VCI Gusseted Bags from Valdamark Direct?

Valdamark Direct strives for efficient service, and as these bags are often held in stock, they are typically available for quick delivery, which is a significant advantage for businesses requiring rapid deployment of corrosion protection.

• How do Daubert Cromwell MetalGuard VCI Gusseted Bags differ from standard plastic bags for metal parts?

The critical difference lies in the integrated VCI technology. Standard plastic bags only offer a physical barrier against dust and moisture, whereas Daubert Cromwell MetalGuard VCI Gusseted Bags actively release corrosion-inhibiting vapors that protect the metal surface at a molecular level, preventing rust and corrosion that a plain bag cannot.

• Can these VCI bags be used in conjunction with other Daubert Cromwell VCI products, like emitters or papers, for enhanced protection?

Yes, for critical or particularly long-term protection, Daubert Cromwell MetalGuard VCI Gusseted Bags are fully compatible with other Daubert Cromwell rust preventative liquids, VCI papers, foams, and emitters. Using them together can provide a multi-layered approach to corrosion control, especially in very large enclosures or for extremely sensitive items.

• What are the cost-saving benefits of using Daubert Cromwell MetalGuard VCI Gusseted Bags over traditional rust prevention methods?

The cost-saving benefits are substantial: they eliminate the need for messy and hazardous oils or desiccants, reduce labor time for cleaning and applying rust preventatives, minimize rework on corroded parts, extend the lifespan of valuable metal components, and streamline the overall packaging process, leading to significant long-term savings.

• How does the self-healing VCI layer in these bags contribute to reliable protection?

The self-healing nature of the VCI layer means that if the protective layer is momentarily disturbed (for instance, by briefly opening the bag), the VCI molecules within the sealed environment will re-vaporize and re-condense on the metal surface, effectively re-establishing the corrosion protection without needing additional product application.