Cortec CorrCap VpCI® Protective Cover

Cortec CorrCap VpCI® Protective Cover

Couldn't load pickup availability

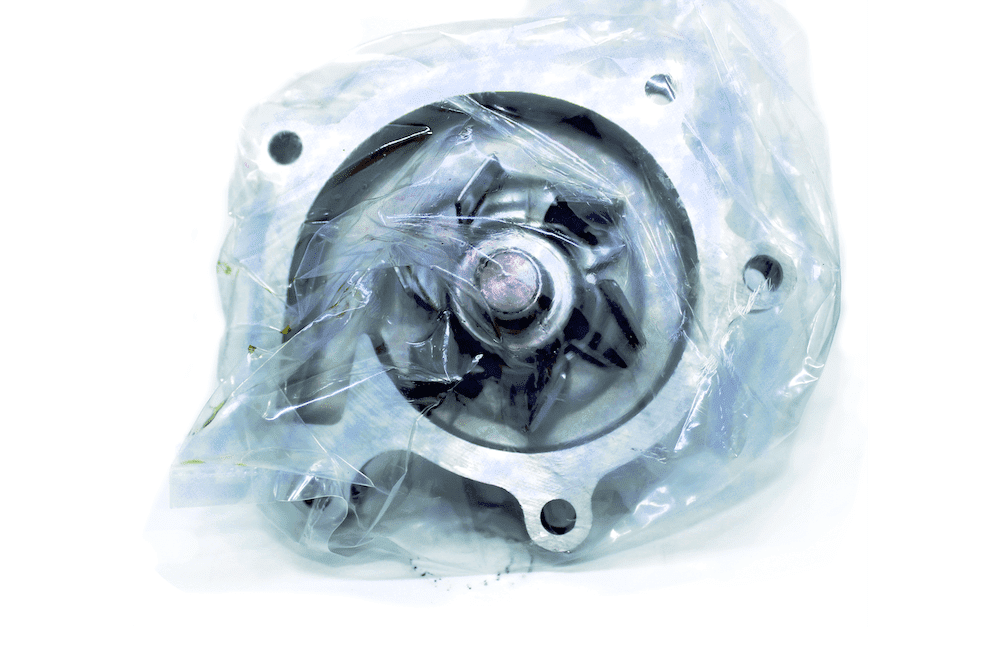

Cortec VpCI® CorrCaps are a cutting-edge, shower cap-style protective cover. It takes corrosion prevention to a whole new level. The product is a globally patented VpCI-126 4 mil film. You use it to safeguard exposed metals during shipments by placing the cap at the edges.

One of the most common applications of our CorrCaps is in the protection of disc braking systems during assembly operations and factory road testing. Once these caps are placed on the ends of the components, a transformative process begins.

The VpCIs (Vapor phase Corrosion Inhibitors) within the film subtly volatilise and migrate with the air, eventually condensing on metal surfaces. This leads to the formation of an incredibly thin, yet remarkably uniform, corrosion-inhibiting barrier. The result is an effective shield that actively combats corrosion, ensuring your valuable components reach their destination in pristine condition.

Features of Protective Cover

This innovative cover provides a comprehensive range of features to ensure your valuable assets remain shielded and corrosion-free.

- Superior Metal Protection: CorrCap VpCI® Protective Cover offers advanced corrosion inhibition technology, providing unparalleled protection for both ferrous and non-ferrous metals. Say goodbye to worries about rust and corrosion, even in harsh environments.

- User-Friendly Design: Designed for effortless application, the CorrCap VpCI® Protective Cover is incredibly easy to use. Its intuitive design allows for quick installation and removal, saving you time and effort.

- Crystal Clear Visibility: Thanks to its transparent composition, this cover allows for easy inspection and monitoring of protected items. You can conveniently check their condition without having to uncover them.

- Flexible and Adaptable: The cover's flexibility ensures it can conform to various shapes and contours, ensuring a snug fit around your equipment or objects, and providing complete coverage and protection.

- Multi metal Protection: Whether you need to protect steel, aluminium, copper, or other metals, CorrCap VpCI® has got you covered. Its versatile formula offers broad-spectrum protection, making it a one-stop solution for all your metal protection needs.

- Customisable Sizes: No matter the size or shape of your assets, CorrCap VpCI® can be tailor-made to fit them perfectly. We understand that every item is unique, and our covers are designed to match your specific requirements.

- Secure Fitment: The cover's secure fit ensures that it stays in place even during transportation or exposure to external forces. You can trust it to keep your metals safe under various conditions.

- Lightweight and Easy to Handle: Weighing only a fraction of traditional metal covers, CorrCap VpCI® is incredibly lightweight, making it easy to handle and install without any additional assistance.

Embrace the future of metal preservation with this high-performance, versatile, and user-friendly protective solution.

Benefits

CorrCap VpCI® employs a highly effective corrosion protection system that shields both ferrous and most non-ferrous metals and alloys. It is environmentally friendly and entirely recyclable. With this solution, you can protect your assets and also contribute to a more sustainable future.

One of the key features of CorrCap VpCI® is its dual action of contact and vapour phase inhibition. This unique combination ensures that corrosion protection extends to every corner, even in hard-to-reach areas. So, no matter the complexity of your metal components, you can trust CorrCap VpCI® to keep them corrosion-free.

Applying the CorrCap VpCI® Protective Cover is a breeze, making it convenient for various industrial and commercial applications. Its user-friendly design allows for easy installation, saving you valuable time and effort.

Don't compromise on the safety of your assets. Choose CorrCap VpCI® to ensure they stay in pristine condition for years to come.

Metals Protected

- Carbon steel

- Stainless steel

- Copper and alloys

- Brass

- Aluminium and alloys

- Zinc

- Galvanised steel

Packaging and Storage

For custom sizes, please contact Cortec for specific sizes and minimum order quantities. Proper storage includes placing the product indoors at room temperature and should be sealed in its original packaging. The protective product is in its best condition within 2 years.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is the Cortec CorrCap VpCI Protective Cover and how does it work?

The Cortec CorrCap VpCI Protective Cover is a unique "shower cap" style cover crafted from a patented VpCI-126 4 mil film, specifically engineered to shield exposed bare metal parts from corrosion during both domestic and international shipments. It works by releasing Vapor phase Corrosion Inhibitors (VpCIs) into the enclosed space, which then subtly volatilize, travel through the air, and condense onto all metal surfaces, forming a thin, effective corrosion-inhibiting barrier that actively combats rust.

• What are VpCIs, and why are they so effective in this product?

VpCIs, or Vapor phase Corrosion Inhibitors, are special chemical compounds that, when released from the CorrCap film, migrate as a vapor and create a protective molecular layer on metal surfaces. This innovative vapor phase action means that even hard-to-reach areas, like crevices and internal cavities, receive comprehensive corrosion protection, making it incredibly effective for complex components.

• What types of metals can the CorrCap effectively protect?

The CorrCap VpCI Protective Cover is designed for broad-spectrum protection, safeguarding a wide range of metals. This includes ferrous metals like carbon steel and stainless steel, as well as non-ferrous metals such as copper and its alloys, brass, aluminum and its alloys, zinc, and galvanized steel.

• How does the CorrCap provide both contact and vapor phase inhibition?

The CorrCap VpCI Protective Cover offers a dual-action protection system. It provides contact inhibition through direct contact with the VpCI-infused film, while simultaneously releasing VpCIs that vaporize and settle on all exposed metal surfaces within the enclosed space, ensuring comprehensive protection, even in areas not directly touching the cap.

• Is the CorrCap designed for long-term or short-term corrosion protection?

The CorrCap is primarily designed for effective corrosion protection during domestic and export shipments, as well as during assembly operations and temporary storage. While it provides robust protection, its typical application involves keeping components safe until they are ready for the next stage of processing or final delivery.

Relevant products you may want to consider:

• What makes the CorrCap transparent, and why is this a useful feature?

The CorrCap is made from a transparent film, which is a really handy feature because it allows for easy visual inspection of the protected items without having to remove the cover. This means you can quickly check the condition of your components, saving time and effort during quality control or pre-inspection.

• How does the "shower cap" style design benefit its application?

The "shower cap" style, with its elastic closure, is incredibly user-friendly. It allows for quick and effortless application, simply by slipping it over the component. This secure fit ensures the cap stays in place even during transit or when exposed to external forces, providing consistent protection.

• What are some common applications where the CorrCap VpCI Protective Cover is utilized?

The CorrCap VpCI Protective Cover finds common use in protecting exposed bare metal parts during various stages. This notably includes safeguarding disc braking systems during assembly operations and factory road testing, as well as covering electrical connectors, engines, and other exposed unfinished components during shipment.

• Can the CorrCap be used for components undergoing factory road testing?

Yes, absolutely! A key application of the CorrCap is indeed the protection of disc braking systems during factory road testing. It remains securely in place throughout this phase, ensuring the components are shielded from corrosion until pre-inspection at the dealer.

• Is the CorrCap suitable for protecting electrical connectors?

Yes, the CorrCap VpCI Protective Cover is frequently used by simply placing it on the ends of electrical connectors to provide essential corrosion protection, ensuring their integrity during storage or transit.

Relevant products you may want to consider:

• How does the CorrCap protect engines or other large exposed components?

For larger components like engines or other exposed parts, the CorrCap is applied to vulnerable surfaces. The VpCIs then volatilize and migrate to all exposed metal surfaces within the enclosed space, offering a comprehensive, invisible shield against corrosion.

• Can this protective cover be used for components during international export?

Yes, the CorrCap VpCI Protective Cover is specifically designed and highly effective for protecting exposed bare metal parts during both domestic and export shipments, ensuring valuable components arrive at their destination in pristine condition.

• In what industrial settings might the CorrCap be particularly useful?

The CorrCap is particularly useful in industries where sensitive metal components are handled, stored, or transported. This includes automotive manufacturing, heavy equipment production, electronics assembly, and any sector dealing with exposed machinery parts that are susceptible to rust and corrosion.

• Can the CorrCap be customized for different component sizes?

Yes, the CorrCap VpCI Protective Cover is highly versatile. It can be custom-made to almost any required size, ensuring a perfect and secure fit for a wide range of components, regardless of their dimensions.

• How does the CorrCap help in streamlining manufacturing processes?

By eliminating the need for messy, traditional rust preventatives like oils that require labor-intensive cleaning, the CorrCap streamlines manufacturing processes. Components protected by CorrCaps are ready for immediate use upon removal, saving significant time and effort in the work-in-progress (WIP) cycle.

Relevant products you may want to consider:

• What are the main benefits of using the Cortec CorrCap over traditional corrosion protection methods?

The primary benefits include a dry and residue-free protection that eliminates the need for cleaning or degreasing, multi-metal compatibility, ease of application and removal, transparency for visual inspection, and its environmentally friendly and recyclable nature. Traditional methods often involve messy applications and hazardous cleaning processes.

• Does the CorrCap leave any residue on the protected metal surfaces?

No, a significant advantage of the CorrCap VpCI Protective Cover is that the VpCIs form an invisible molecular layer that does not leave any sticky or oily residue on the metal surfaces. This means components are ready for immediate use upon removal.

• How does the CorrCap contribute to environmental sustainability?

The CorrCap is an environmentally friendly option as it is recyclable and non-toxic, not relying on harmful chemicals like nitrites. By using this product, businesses can reduce their environmental footprint and contribute to a more sustainable future compared to traditional oil-based rust preventatives that often require special disposal.

• Is the CorrCap lightweight and easy to handle?

Yes, the CorrCap is designed to be incredibly lightweight, making it very easy to handle and install without needing additional assistance, which is a stark contrast to some heavier, more cumbersome traditional protective covers.

• Does the CorrCap offer protection even in challenging environments?

While designed primarily for enclosed spaces during transit and storage, the VpCI technology within the CorrCap provides effective corrosion protection that can withstand typical environmental fluctuations encountered during shipment and indoor storage, ensuring protection even in potentially harsh conditions.

Relevant products you may want to consider:

• Can the CorrCap help reduce overall operational costs?

Absolutely. By eliminating the need for costly and time-consuming cleaning and degreasing steps associated with traditional rust preventatives, and by preventing corrosion-related damage and rework, the CorrCap significantly reduces overall operational costs and improves efficiency.

• How does the CorrCap improve product quality upon delivery?

The CorrCap ensures that metal components arrive at their destination in pristine, corrosion-free condition. This directly translates to improved product quality and customer satisfaction, as there's no need for post-shipment cleaning or dealing with rust-related issues.

• What is the thickness of the film used in the Cortec CorrCap?

The Cortec CorrCap VpCI Protective Cover is made from a VpCI-126 4 mil film, providing a robust and effective barrier against corrosion.

• How should the CorrCap VpCI Protective Cover be stored to maintain its effectiveness?

To ensure the CorrCap maintains its effectiveness, it should be stored indoors at room temperature and kept sealed in its original packaging. This proper storage helps preserve the integrity of the VpCI film.

• What is the recommended shelf life for the CorrCap when stored correctly?

When stored indoors at room temperature and sealed in its original packaging, the CorrCap VpCI Protective Cover has a shelf life of up to 24 months.

Relevant products you may want to consider:

• Can the CorrCap be reused?

Yes, the CorrCap VpCI Protective Cover can be reused for up to one year, which adds to its cost-effectiveness and sustainability benefits.

• Does the CorrCap require any special surface preparation before application?

No, one of the key advantages of the CorrCap is its user-friendly application. It does not require any special surface preparation, such as cleaning or degreasing, before it is applied to the metal component.

• How does the CorrCap's secure fit ensure continuous protection?

The elastic design of the CorrCap ensures a snug and secure fit around the component, meaning it stays reliably in place. This secure fit is crucial for maintaining the enclosed micro-environment where the VpCIs can effectively volatilize and protect the metal surfaces continuously.

• What happens if the CorrCap is repeatedly opened and closed?

Even if the package is repeatedly opened and closed, the VpCI barrier provided by the CorrCap is self-replenishing. This means the VpCIs continue to protect the metal surfaces, ensuring continuous corrosion inhibition.

• Are there any specific safety considerations when using the Cortec CorrCap?

While the CorrCap is generally safe for personnel and the environment, it is designed for industrial use only. It's always a good practice to consult the Material Safety Data Sheet (MSDS) for more detailed information and to keep the product out of reach of children.