Automotive Packaging Company ICI Reveals New Bumper Solution | Valdamark Packaging

Alex ToddWith the Best Packaging in the Industry, ICI’s hybrid pallet box design allows up to two Front Bumpers and three Rear Bumpers to be stacked on top of each other.

As far as automotive packaging companies go ICI is really leading the innovation charge with this new solution.

The Hybrid pallet box solution is a design that allows for extreme space utilisation. Typically these kind of pallet boxes only allow 1 Or 2 bumper maximum for shipping. The ICI packaging solution allows for two front bumpers and three rear bumpers to each be stacked on top of each other.

Each bumper part is fully enclosed with the pallet box and fits snugly thus to save space and to ensure the parts do not move when being handled in the supply chain.

Consider alternative correlated products that simply box the valuable automotive parts with shrink wrap. This leaves the parts open and exposed to both damage from the elements and poor handling.

This packaging design is simple but effective. It will definitely prevent shipping damage in my opinion, as well as improving space saving efficiency.

Speaking of damage this product has a outstanding record.

Shipping Damage Indicators are also used during transport and storage. However so far they have not recorded a single breakage. This 0% defect rate is particularly impressive as freight of these weights and dimensions will usually experience at least 5% that are damaged in transit and not in factory condition.

Other innovations

Replacing Polystyrene Foam with Poultry Feathers

An automotive packaging company, Aeropowder, is finding a new way to make eco-friendly materials. They are using waste chicken feathers instead of non-biodegradable plastic (Polystyrene). Polystyrene is commonly used in cars, but it's bad for the environment. Aeropowder wants to create packaging that is better for nature. They use feathers because they can keep things warm or cold. This company is trying to replace the old plastic with a new, sustainable option.

Corrosion-Free Packaging for Sustainable Transit

The Automotive Packaging Company, Smurfit Kappa, created a new type of packaging that protects car parts during shipping. It prevents them from getting rusty. They use something called VCI, which is a clear and odourless layer. This keeps the parts rust-free, so you can use them right away without cleaning.

Tailored Packaging Solutions for the Automotive Industry

The automotive sector is a significant part of the global packaging market. Its share in the market is 40% or more. To meet the demands of long-distance shipping, Nefab Group designed ExPak. These boxes are wooden crates with custom inner fittings. They provide a flexible and space-efficient solution. These boxes are tailored to the specific needs of parts, reducing the risk of damage during transit. Additionally, they maximise the efficient use of space, helping companies save on shipping costs and storage.

Protection from Vibrations

Pregis LLC presents a groundbreaking solution with their Polypropylene Foam Sheet. This low-density foam boasts a high friction coefficient, effectively shielding products from vibrations and preventing shifting during transportation. Furthermore, Microfoam is stable and remarkably lightweight, making it a versatile choice for automotive packaging.

Induction Heat Sealer: Ensuring Leak-Proof Automotive Packaging

In the automotive packaging industry, preventing leaks is of paramount importance. Sealing through Induction heat offers a tamper and leak-proof sealing method. Enercon Ind Ltd. specialises in Automotive Products, ensuring that automotive fluids like oil and grease arrive at their destination without any leakage. This technology provides a robust solution for safeguarding automotive products during transit.

Dispensing Closure With Enhanced Safety

To make applying oils and greases to car parts safer and more convenient, Silgan Systems created special caps. These caps have a spout for pouring liquids exactly where you want them. They come in different sizes, so you can choose the one that fits your needs. What's more, these caps are designed to be hard for children to open, making them child-safe. This innovation not only improves safety but also makes the process of using oils and greases more precise and user-friendly for the automotive industry.

Laser Coding in automotive Labels

Car parts need labels with important safety info and barcodes that can handle being put together, kept in stock, and serviced multiple times. Linx Printing Tech has a solution. They use lasers to put permanent codes. These labels can go on many glass, rubber, and other compatible materials. This makes sure the labels last for a long time on different car parts. Plus, it's a cost-effective alternative to printing labels in advance.

Re-inscribable Labels: A Revolution in Component Marking

Schreiner has introduced a game-changing method for labeling car parts during assembly. They use a unique system that lets air pass through while putting permanent labels on components. This innovative approach ensures that self-adhesive labels are automatically affixed to the parts, simplifying the process and eliminating the need for extra labelling steps. This not only saves time but also streamlines the assembly and labelling of automotive components, making it a more efficient and cost-effective solution for the automotive industry.

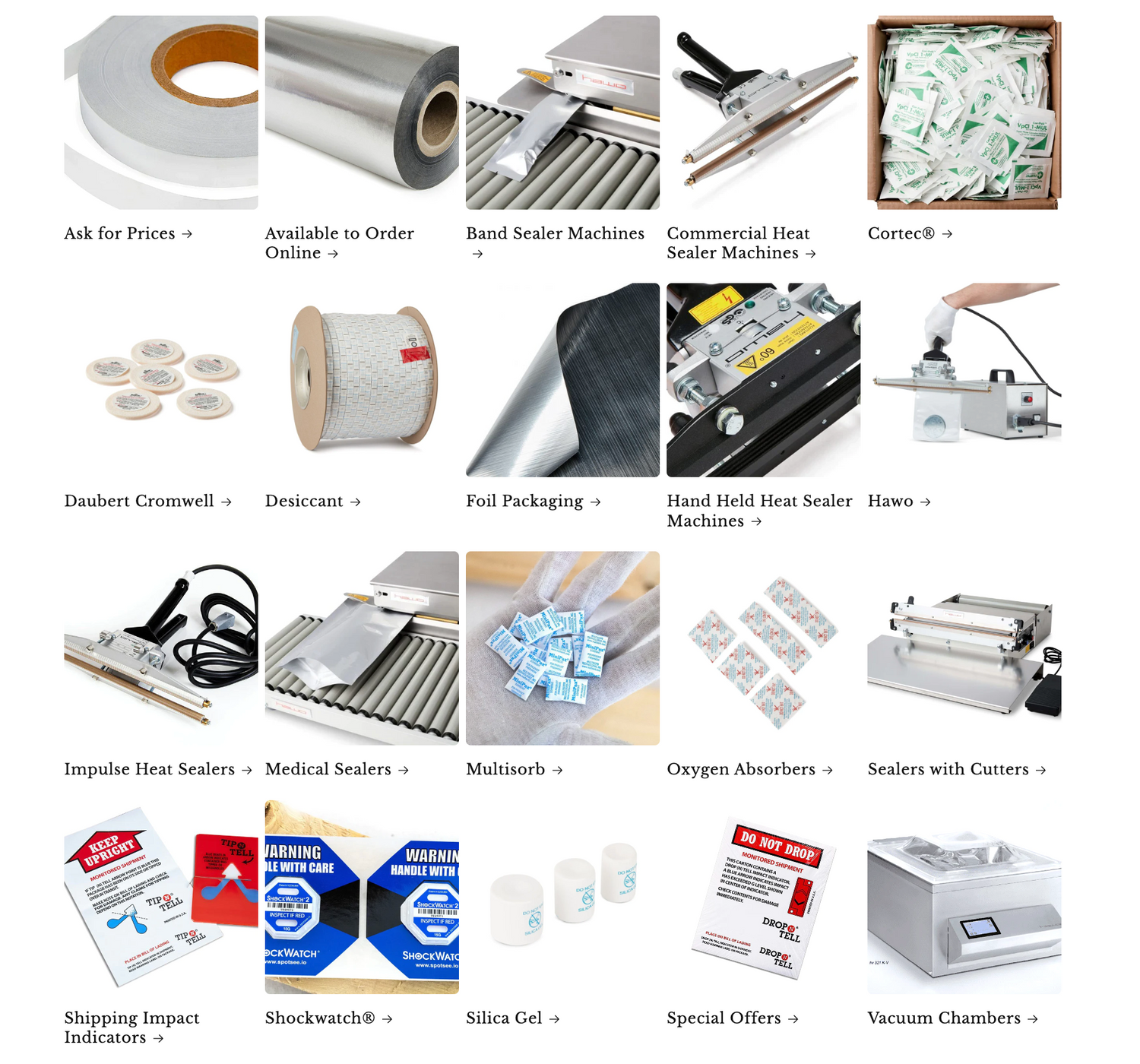

Get in touch to discuss your Shockwatch and Tip N Tell requirements.