Shockwatch® 2 Bundle Package (Including Companion Shipping Labels)

Shockwatch® 2 Bundle Package (Including Companion Shipping Labels)

Couldn't load pickup availability

Shockwatch self adhesive labels each contain a vial designed to break relative to the colour coded range.

Once damage occurs the vial breaks instantaneously releasing a red dye that will clearly indicate to the receiving party that poor handling has occurred.

ShockWatch 2 indicator labels attach conveniently onto your shipment as a solution to prevent and deter bad handling from shipping and transportation services.

These units raise awareness that the shipment is fragile and being monitored. ShockWatch Labels offer more than just a visual deterrent. They have real cost saving potential for damages incurred due to poor handling. As well as an improved brand perception for commitment to defect free deliveries.

Shockwatch shipping labels continually prove themselves to be highly effective in the modern supply chain. Allowing a cost effective and convenient solution for preventing shipping damage.

With goods travelling at greater volumes than ever before it’s no surprise that freight damage costs industry millions a year. Third party shipping services nearly always put emphasis on speed. As opposed to the attention and quality of care the shipments themselves receive.

This inconvenience is too great for business to ignore. Damage to goods, damage to reputation and of course the cost of replacement is truly damaging to competitive industry. Choose Shockwatch impact labels to add accountability and improve brand perception. They demonstrate to your clientele that you take shipping quality seriously.

Shockwatch benefits include the following:

- Protection of delicate, sensitive or precision goods.

- Potential production increase.

- Shows evidence of damage during transport.

- Act as a deterrent poor handling.

- Potential bottom line cost savingsImproved customer satisfaction.

Due to their versatility Shockwatch Indicators are commonly used in industries like:

- Automotive.

- Precision components.

- Electrical goods.

- Defence packaging.

- Science & Medical.

- Furniture and Home wares.

- Media.

- Export Case making and Export packing.

How do they work ?

See below advice on fitting based on our two most popular units.

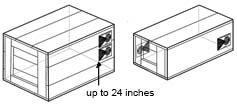

Purple unit measuring 37G at 50 milliseconds

Purple Shockwatch BoxFor lighter cartons we recommend a Shockwatch sticker placed at 24″ in an upper corner of the box.

For larger/heavier cartons, Octabins or pallet freight we recommend the use of 2 labels. Place these labels on opposing ends diagonally facing each other.

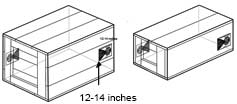

Yellow label measuring 25G at 50 milliseconds

Attach Shockwatch 25g label 12 – 14 inches for carton bottom.

Yellow Shockwatch BoxFor heavier items. Attach two shock labels on opposite ends of the box facing diagonally facing each other.

As a general run packages that have a length twice the width are classed as ‘heavier items’.

Please note – this product is intended for use by appropriate trained or qualified professionals or trades people. The advice given on our selection chart for colour compatibility is reliable. However it is given in good faith and is by no means exhaustive for all products and shipments.

Delivery Time

VpCI® 150's versatility makes it the ultimate ally for corrosion prevention, keeping your valuable assets performing at their best.

1-2 Business Days UK.

For more information on Shock label products visit our Tiltwatch page.

Frequently Asked Questions

• What exactly are Shockwatch Labels, and what’s their primary purpose?

Shockwatch Labels are clever, tamper-proof, mechanically-activated devices designed to visibly indicate when a package has experienced a potentially damaging impact during transit or storage. Their main goal is to deter mishandling and, ultimately, help businesses reduce costs associated with product damage.

• How do Shockwatch Labels work to detect impacts?

These labels contain a small vial of red liquid, held in suspension. When the package experiences an impact that exceeds a pre-determined G-force threshold, this shock disrupts the liquid's surface tension, causing the highly visible red dye to release and permanently stain the tube, indicating mishandling.

• Are Shockwatch Labels reusable once they've been activated?

No, Shockwatch Labels are designed for single use and are tamper-proof. Once the internal indicator turns red due to an impact, it cannot be reset, ensuring that the evidence of mishandling is clear and permanent.

• What does the "G-force" rating on a Shockwatch Label signify?

The G-force rating, often seen as 25G, 37G, 50G, 75G, or 100G, indicates the specific level of impact acceleration (G-force) that is required to activate the label. A lower G-force number means the label is more sensitive and will trigger with a lighter impact.

• How can I tell if a Shockwatch Label has been activated?

It's quite straightforward! If a Shockwatch Label has been activated, the circular indicator in the center of the label will show full or partial red coloration. Any visible red in that window is your clear sign that the package has experienced an impact beyond its designated threshold.

Relevant products you may want to consider:

• How do I select the correct G-force sensitivity for my specific shipment?

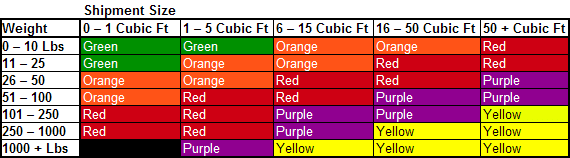

Choosing the right sensitivity for a Shockwatch Label depends primarily on the size and weight of your shipment, as well as the fragility of the contents. Heavier and bulkier items generally require less sensitive labels (higher G-force ratings), while lighter, more delicate items need higher sensitivity (lower G-force ratings). The valdamarkdirect.com product page provides a helpful selection guide based on package dimensions and weight.

• What are the different G-force sensitivities available for Shockwatch Labels?

Shockwatch Labels are available in a range of sensitivities, typically colour-coded for easy identification: L-30 (Green - 100G), L-35 (Orange - 75G), L-47 (Red - 50G), L-55 (Purple - 37G), and L-65 (Yellow - 25G). This spectrum allows you to match the label precisely to your product's fragility.

• If my package is very fragile, which Shockwatch Label should I choose?

For extremely fragile items, you would typically opt for the most sensitive Shockwatch Labels, which are the lower G-force ratings. The Yellow L-65 (25G) label is generally recommended for highly delicate goods, as it will indicate even relatively light impacts.

• Are there situations where I might need to use more than one Shockwatch Label on a package?

Yes, for very large or irregularly shaped packages, or for palletised shipments, it's often recommended to use two Shockwatch Labels. Placing a second indicator in the same position on the opposite side of the package ensures more comprehensive monitoring of potential impacts.

• Does the type of packaging material affect the G-force sensitivity I should select?

Indeed, it can. If your packaging design is exceptionally robust and your product experiences a low damage rate, you might consider using an indicator with slightly less sensitivity. Conversely, if your packaging offers minimal protection, a more sensitive label would be prudent.

Relevant products you may want to consider:

• Where is the optimal placement for a Shockwatch Label on a package?

While Shockwatch Labels can detect mishandling regardless of placement, for best sensitivity, it's generally recommended to place them on the upper right corner or along the right edge of the longest side of the package. For heavier shipments, a lower mounting position might be more appropriate.

• Do I need any special tools or equipment to apply Shockwatch Labels?

No, not at all! Shockwatch Labels feature a strong pressure-sensitive acrylic adhesive, making them incredibly easy to apply by hand directly to your package. Simply peel off the backing and press firmly onto a clean, dry surface.

• Can Shockwatch Labels be applied directly to the product itself, or only to the packaging?

Shockwatch Labels are versatile; they can be effectively affixed to the product packaging, or in some cases, directly onto the product itself, offering flexibility in how you choose to monitor your goods.

• What are "Companion Labels" and why are they important when using Shockwatch Labels?

Companion Labels are supplementary labels that are often used alongside Shockwatch Labels. They serve as an unmistakable visual warning that the package is being monitored for mishandling and provide clear instructions to receiving personnel on what actions to take if the Shockwatch indicator has been activated.

• Is there a recommended storage method for unused Shockwatch Labels to maintain their effectiveness?

To maintain their optimal performance and two-year shelf life, Shockwatch Labels should be stored at standard temperature and pressure (around 20°C or 68°F and 1 ATM), in a non-condensing environment, and kept in their original packaging until ready for use.

Relevant products you may want to consider:

• How can Shockwatch Labels help my business reduce product damage and loss?

By providing a clear visual indication of mishandling, Shockwatch Labels deter improper handling throughout the supply chain. This awareness often leads to improved handling practices, significantly reducing instances of product damage and the associated costs of loss.

• Do Shockwatch Labels offer indisputable evidence of mishandling for freight claims?

Yes, they do. An activated Shockwatch Label provides indisputable, tamper-proof evidence that a package has been subjected to an impact exceeding its designated G-force threshold, which can be invaluable when filing or resolving freight claims.

• Beyond direct damage, what other benefits do Shockwatch Labels offer in terms of supply chain accountability?

Shockwatch Labels foster a greater sense of accountability among all parties involved in the supply chain – from dispatch to delivery. Knowing that mishandling will be detected encourages better practices, helps pinpoint problem areas, and can lead to more efficient and reliable logistics.

• Can using Shockwatch Labels improve customer satisfaction?

Absolutely. When customers consistently receive their fragile goods in perfect condition, it significantly enhances their satisfaction and trust in your brand. Shockwatch Labels directly contribute to this by ensuring products arrive as intended, minimizing the hassle of returns or replacements.

• How do Shockwatch Labels act as a deterrent to improper handling?

The highly visible presence of a Shockwatch Label on a package serves as an immediate warning to handlers that the contents are sensitive and are being monitored. This visual deterrent often leads to more careful handling, even before any impact occurs.

Relevant products you may want to consider:

• For what types of products or industries are Shockwatch Labels particularly useful?

Shockwatch Labels are incredibly versatile and are used across a wide array of industries and for various products, including high-tech equipment, medical devices, scientific instruments, automotive and truck parts, industrial machinery, glass products, sensitive electronics, furniture, and even fine art.

• Can Shockwatch Labels help monitor the transit of calibration-sensitive equipment?

Indeed. For items that are sensitive to calibration shifts due to impacts, Shockwatch Labels are ideal. They provide critical evidence if the equipment has been mishandled, allowing for inspection or recalibration before it's put into use, thus preventing potential functional issues.

• Are Shockwatch Labels used in the energy and utilities sector?

Yes, they are. In the energy and utilities sector, where sensitive and often heavy components are frequently transported, Shockwatch Labels are used to ensure these critical items arrive undamaged, safeguarding operational integrity.

• How do Shockwatch Labels assist in quality control processes?

By providing clear evidence of impacts, Shockwatch Labels can be integrated into quality control procedures. They help identify if damage occurred during shipping rather than during manufacturing or internal handling, allowing businesses to pinpoint and address issues within their supply chain.

• Can these labels be used for international shipments, given varying handling practices?

Absolutely. Given the varied handling practices that can occur in international shipping, Shockwatch Labels are particularly valuable. They provide a universal, unambiguous signal of mishandling, regardless of language barriers or local regulations, promoting accountability across global supply chains.

Relevant products you may want to consider:

• What is the operating temperature range for Shockwatch Labels?

Shockwatch Labels are designed to be quite robust, with an operating temperature range typically from -25°C to 80°C (-13°F to 176°F), ensuring their functionality in a wide variety of climatic conditions encountered during transit and storage.

• Do Shockwatch Labels have a defined shelf life?

Yes, when stored correctly under standard temperature and pressure conditions, Shockwatch Labels typically have a shelf life of up to two years from their date of sale, ensuring they remain effective when you need them.

• Are Shockwatch Labels tamper-proof, and how is this achieved?

Shockwatch Labels are indeed designed to be tamper-proof. Their mechanical activation mechanism is irreversible, and many labels also incorporate unique serial numbers, making it difficult to swap or manipulate them without detection.

• What adhesive is used on Shockwatch Labels?

Shockwatch Labels utilize a high-performance acrylic adhesive, which ensures a strong and secure bond to various packaging materials, making them resistant to accidental detachment during transit.

• Do Shockwatch Labels comply with any specific industry standards or certifications?

Yes, Shockwatch products are often tested and produced to high standards, and many are backed by certifications such as ISO 9001 and compliance with various transportation regulations, ensuring their reliability and quality in demanding logistical environments.