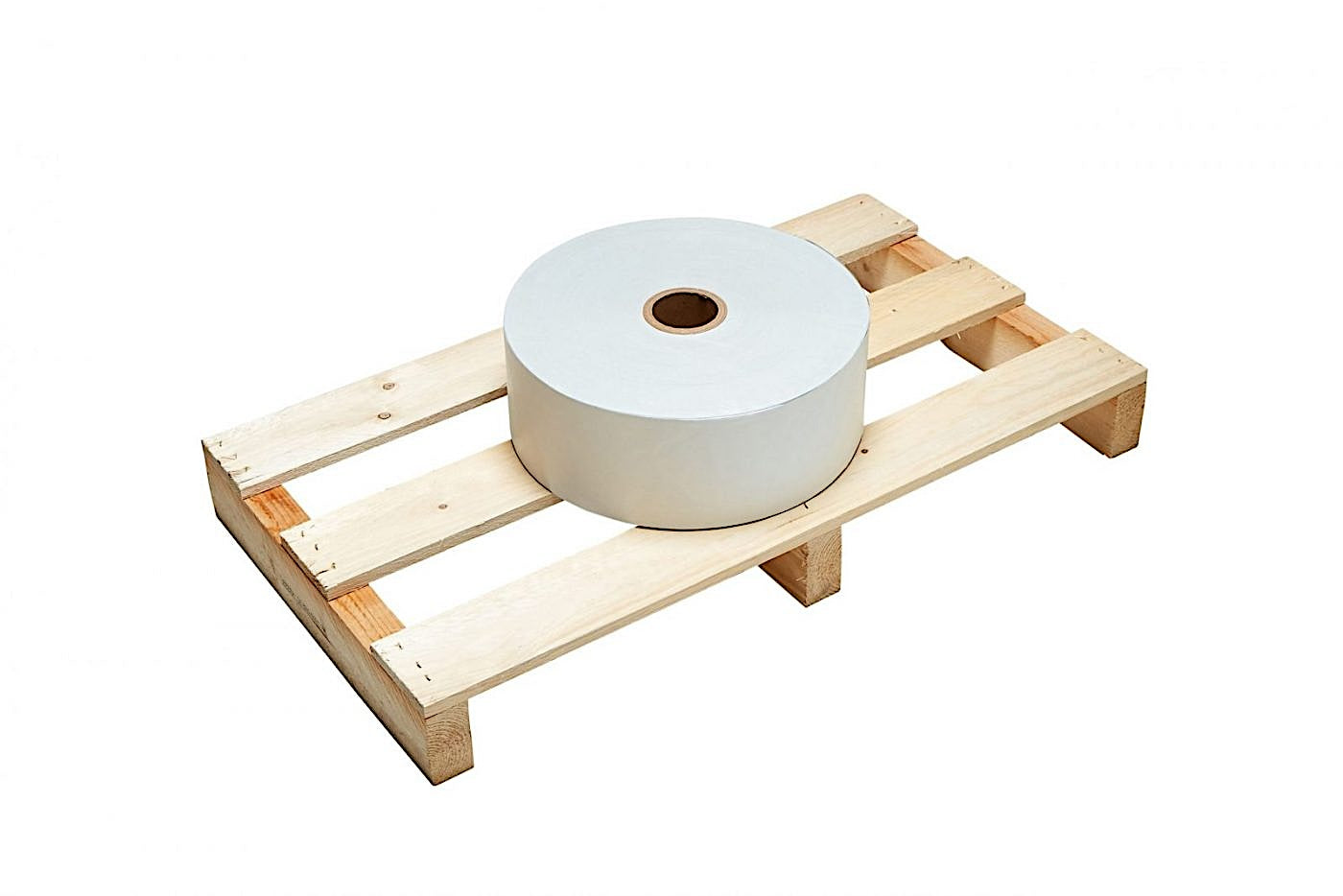

PE Foil Packaging Thermoplastic Film

PE Foil Packaging Thermoplastic Film

Stock TBD

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Valdamark’s PE foil extrusions and laminations are usually coated/bonded to other base materials in accordance with the client’s specification.

A speciality product we can meet the majority of multi layered PE Foil requirements, as well as most packaging film constructions in general.

In addition to our standard pre-cut roll stocks, we specialise in high volume usage films, both commodity and technical in nature.

This diverse range of applications means that we serve a wide variety of markets and sectors.

Sectors include:

- Industrial.

- Aerospace & Automotive.

- Agro foods.

- Energy, Oil, Gas & Nuclear (PMUC).

- Building/Construction.

- Healthcare/Pharmaceutical.

- Humanitarian.

- Security, anti-counterfeiting.

- Asset protection & preservation.

Our production and conversion capabilities are such that in addition to the raw material itself we can convert PE Foil bases into a variety of ‘finished formats’ including:

- Octabin Liners.

- Bulk Bags.

- Gusset Bags.

- Spouted Bags.

- 3D & 2D Box Bags.

- Vented Sacs.

- LDPE Foil.

Our machinery enables us to take a unique approach to design and development.

- Automated Pouch Machine.

- Bag Forming Machine.

- Printing.

- Large Selection of Custom Tooling.

- 24-hour shift production.

- High volume/capacity production machinery capable of producing 1000’s pieces per hour.

Often in conjunctions with

- In House R & D – Doping, extrusion, lamination & seal strength testing facilities all available in house.

- Third Party R & D – We work with a leading 3rd party corrosion testing laboratory as well as sterilised and clean room finishing facilities.

- Fast turnarounds for customisations & prototypes.

- Partner with several leading ISO/IEC-17025:2005 accredited testing laboratories.

- Both ISO 9001 & ISO 14001 compliant

Frequently Asked Questions

• What exactly is PE foil and why is it so widely used in packaging?

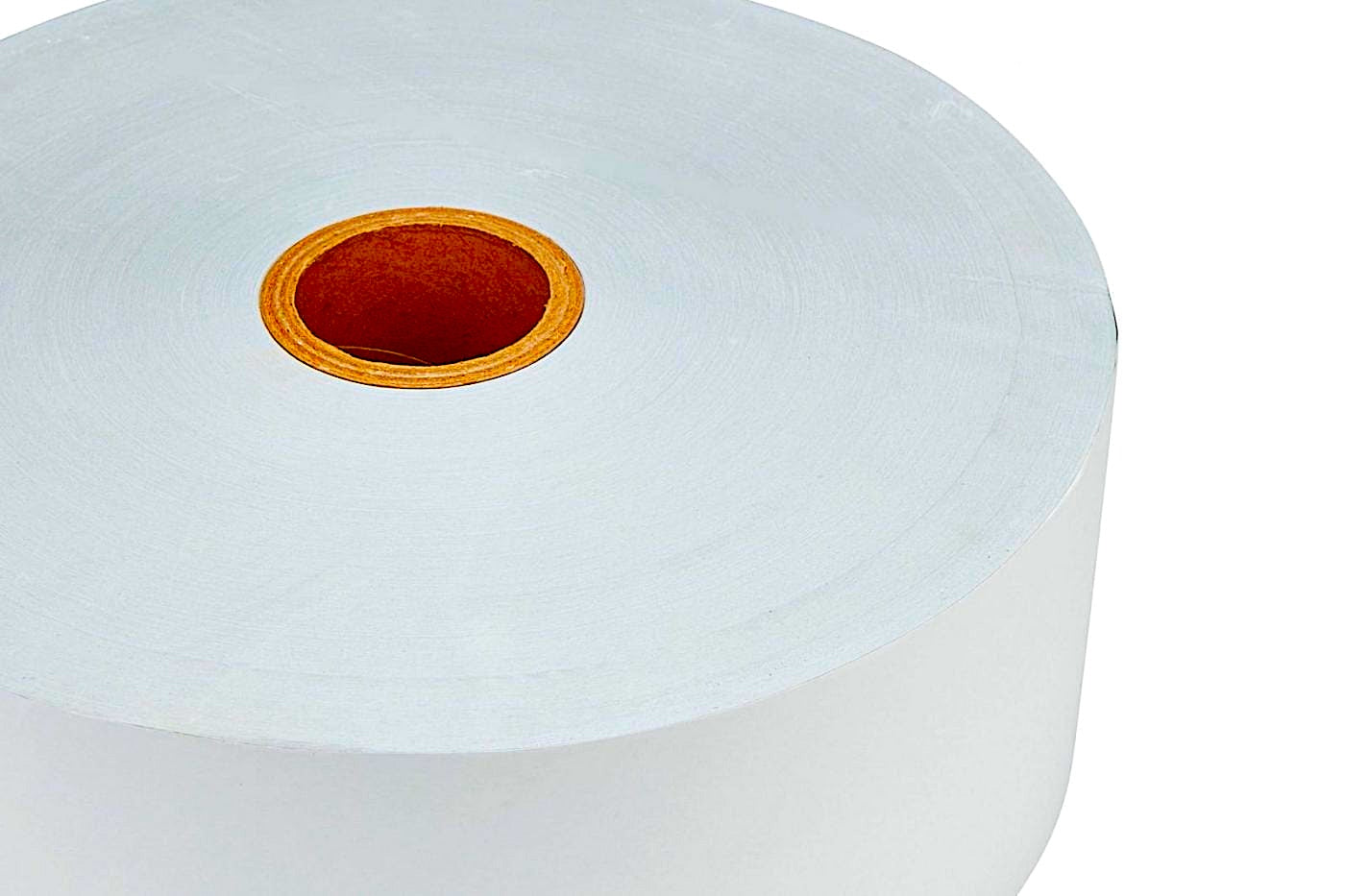

PE foil, which stands for Polyethylene foil, is a highly versatile thermoplastic film primarily used in packaging. Its popularity stems from its excellent properties, such as its barrier capabilities against moisture, gases, and odours, as well as its strength and flexibility, making it ideal for protecting a vast array of products.

• How does Valdamark Direct's PE foil differ from other types of plastic films?

Valdamark Direct specialises in PE foil extrusions and laminations that are often custom-coated or bonded to other materials, setting them apart. This allows for highly tailored solutions, meeting complex multi-layered requirements and a wide range of packaging film constructions beyond standard off-the-shelf options.

• Is Valdamark Direct's PE foil considered an environmentally friendly packaging option?

While the content doesn't explicitly state biodegradability for all PE foil, polyethylene itself is a widely recyclable plastic, and Valdamark Direct emphasizes its commitment to quality and diverse applications, which often includes optimising material usage. For specific environmental certifications, it's always best to check the product's individual specifications.

• What are the core properties that make PE foil a great choice for packaging?

The key properties of PE foil include its excellent barrier against water vapour and gases, its inherent strength and flexibility, and its resistance to oils, greases, and various chemicals. These characteristics make it a robust and reliable material for safeguarding packaged goods.

• Can Valdamark Direct supply PE foil for both small-scale and high-volume packaging needs?

Absolutely! Valdamark Direct is equipped to handle both standard pre-cut roll stocks for everyday use and specialises in high-volume usage films, catering to both commodity and technical requirements. This means they can serve businesses of all sizes, from small operations to large industrial clients.

Relevant products you may want to consider:

• In which industries does Valdamark Direct's PE foil commonly find its application?

Valdamark Direct's PE foil serves a broad spectrum of markets and sectors, including industrial, aerospace & automotive, agro-foods, energy (oil, gas & nuclear, particularly PMUC compliant), building/construction, healthcare/pharmaceutical, humanitarian, security, anti-counterfeiting, and general asset protection & preservation. Its versatility makes it a go-to for diverse needs.

• How is PE foil used in the building and construction sector?

In building and construction, PE foil serves various critical roles, often as a covering foil, a robust vapour barrier to prevent moisture ingress, or for protecting surfaces during construction and renovation projects. It's used for covering furniture, materials, fresh concrete, and as a subfloor.

• Can PE foil be used for protecting sensitive equipment during shipping and storage?

Yes, definitely. PE foil, especially when part of a multi-layered or barrier foil construction, is an excellent choice for protecting sensitive equipment from environmental factors like moisture, oxygen ingress, UV light, and temperature extremes during transport and long-term storage.

• What are some specific packaging formats that Valdamark Direct can create using PE foil?

• Is Valdamark Direct's PE foil suitable for food contact applications, such as agro-foods?

Yes, Valdamark Direct works with PE foil for the agro-food sector, indicating its suitability for food contact applications. For specific food-grade certifications, it's always best to inquire about the particular PE foil product's compliance.

Relevant products you may want to consider:

• How does PE foil contribute to asset protection and preservation?

PE foil, especially when incorporated into high-performance barrier laminates, forms an effective shield against moisture, oxygen, and other external elements that can lead to corrosion or degradation of assets. This protection is crucial for preserving the integrity and value of stored or transported goods.

• What role does PE play when laminated with other materials like aluminium foil?

When PE is laminated with materials like aluminium foil, it often serves as a bonding layer or an additional barrier. For instance, in aluminium barrier foils, PE layers help bond the aluminium to other materials, while also contributing to the overall barrier properties against water vapour and gases.

• Can Valdamark Direct's PE foil provide a complete barrier against gases and liquids?

While thinner gauges of PE foil allow some transmission, heavier gauges, particularly when integrated into multi-layered laminates like Valdamark Direct's high-performance barrier foils, are designed to provide a near-complete barrier against gases and liquids, crucial for sensitive product protection.

• How does the thickness of PE foil impact its performance?

Generally, a thicker PE foil offers enhanced strength and barrier properties. For instance, in construction, thicker films (e.g., 90-200 microns) are recommended for more demanding applications like road construction or damp-proofing, while thinner films (e.g., 30-50 microns) are suitable for lighter covering tasks.

• Does Valdamark Direct's PE foil offer heat sealability?

Yes, polyethylene is a thermoplastic, meaning it can be heat-sealed. This characteristic is vital for creating hermetically sealed packaging, which is essential for protecting contents from the external environment and is often a key feature in Valdamark Direct's packaging solutions.

Relevant products you may want to consider:

• Is Valdamark Direct's PE foil resistant to tears and punctures?

The strength and tear resistance of PE foil can vary depending on its specific formulation and whether it's part of a multi-layered construction. Valdamark Direct emphasizes its speciality in meeting diverse requirements, suggesting they can provide PE foil engineered for specific strength and puncture resistance needs.

• Can Valdamark Direct provide PE foil with anti-static properties for electronics packaging?

While the direct product page doesn't explicitly mention anti-static PE foil, the aerospace & automotive sector, where static discharge can be critical, is listed as a served industry. It's highly probable that Valdamark Direct can offer PE foil solutions with anti-static properties if required for sensitive electronics.

• What kind of customisation options are available for Valdamark Direct's PE foil?

Valdamark Direct excels in customisation, offering PE foil extrusions and laminations that can be coated or bonded to other base materials according to a client's specific requirements. They can meet the majority of multi-layered PE foil needs and general packaging film constructions, even providing fast turnarounds for customisations and prototypes.

• Does Valdamark Direct offer printing on their PE foil products?

Yes, their machinery capabilities include printing, which means Valdamark Direct can provide PE foil that is custom-printed, allowing for branding, product information, or other visual elements on the packaging.

• Can Valdamark Direct produce bespoke PE foil bags and liners?

Absolutely. Valdamark Direct manufactures to order, providing custom packaging services where 2D and 3D foil packaging bags and liners can be converted to your chosen sizes. This flexibility is a significant advantage for unique packaging challenges.

Relevant products you may want to consider:

• How quickly can Valdamark Direct deliver custom PE foil orders?

Valdamark Direct highlights fast turnarounds for customisations and prototypes, indicating their efficiency and commitment to meeting client deadlines for bespoke PE foil products.

• Does Valdamark Direct work with external laboratories for product development and testing?

Yes, in addition to their in-house capabilities, Valdamark Direct collaborates with several leading ISO/IEC-17025:2005 accredited testing laboratories. This partnership ensures that their products meet stringent technical requirements and are rigorously tested for performance.

• How does Valdamark Direct ensure the quality of their PE foil products?

Valdamark Direct is ISO 9001 and ISO 14001 compliant, which signifies their commitment to quality management and environmental responsibility in their manufacturing processes, ensuring high standards for their PE foil products.

• Can I purchase standard PE foil rolls directly from Valdamark Direct's website?

Yes, for convenience, Valdamark Direct offers several of their standard-sized and formatted PE foil products available for purchase directly online, alongside their bespoke manufacturing services.

• What is the typical lead time for standard PE foil orders from Valdamark Direct?

While specific lead times aren't detailed for standard orders, Valdamark Direct's emphasis on high-volume/capacity production machinery and fast turnarounds suggests they aim for efficient delivery. For precise lead times, contacting them directly would be best.

Relevant products you may want to consider:

• How can I get advice on choosing the right PE foil for my specific application from Valdamark Direct?

Valdamark Direct encourages direct communication to discuss specific requirements. Given their specialisation in custom solutions and technical products, their team would be best placed to offer tailored advice on choosing the ideal PE foil.

• What other types of flexible packaging solutions does Valdamark Direct offer alongside PE foil?

Beyond PE foil, Valdamark Direct offers a comprehensive range of flexible packaging solutions, including high-performance barrier foil packaging (like their VAL55HD™ heat-sealed foil rolls), VCI (Volatile Corrosion Inhibitor) bags and film, and various heat sealing machines to work with these materials.

• Does Valdamark Direct provide heat sealing equipment compatible with their PE foil?

Yes, Valdamark Direct is a specialist in heat sealing solutions, offering a diverse range of high-quality heat sealing machines, including manual, semi-automatic, and fully automated models, which are compatible with thermoplastic materials like PE foil for effective sealing.

• Can Valdamark Direct provide a complete packaging solution, from film to sealing equipment?

Absolutely. Valdamark Direct positions itself as a comprehensive provider, offering both made-to-order foil packaging (including PE foil solutions) and a wide array of heat sealing machines, allowing clients to source both the material and the equipment from a single, trusted supplier.

• How does Valdamark Direct's PE foil integrate with corrosion prevention strategies?

Valdamark Direct's PE foil, particularly when used in combination with their VCI products or as a component in their barrier foil laminates, plays a crucial role in corrosion prevention by creating an effective barrier against moisture and other corrosive elements, thereby safeguarding metal goods during storage and transport.

Relevant products you may want to consider: