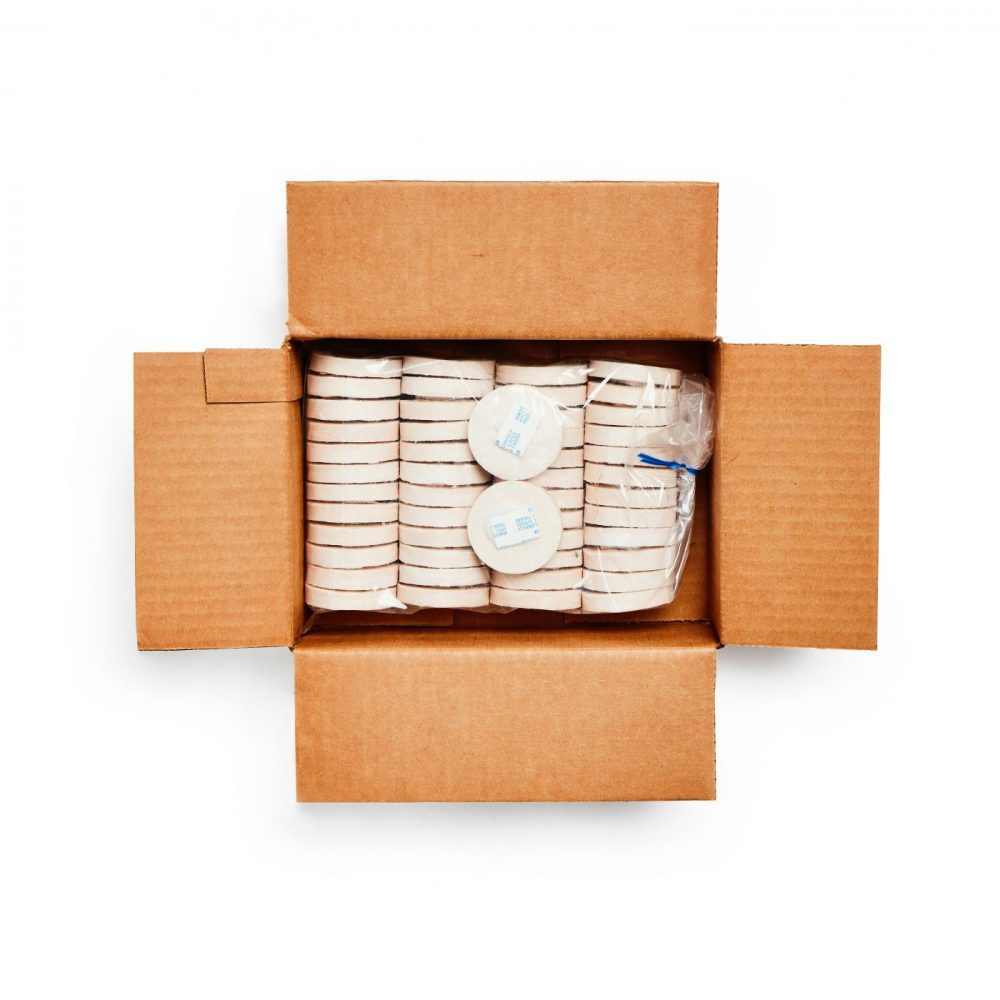

Daubert Cromwell Daubrite Disk 5 & 10 VCI Emitter Pads - Non Woven Fabric

Daubert Cromwell Daubrite Disk 5 & 10 VCI Emitter Pads - Non Woven Fabric

26 in stock

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Daubrite VCI emitter pads from Daubert Cromwell® combine the proven Daubert VCI corrosion inhibitor chemistry with a compact emitter pad device for use in enclosed or inside packaging environments.

Daubrite VCI emitter pads are corrosion prevention devices designed to protect sensitive metals from within packaged and enclosed environments.

Each Daubrite VCI emitter is made from a robust non-woven fabric which contain the sophisticated Daubert Cromwell VCI corrosion inhibitor formula. The Daubrite 5 disk protects up to 5 cubic feet, whilst the Daubrite 10 disk can reach up to 10 cubic feet.

Each emitter pad is backed by a piece of self adhesive tape for easy installation. When fixed in place, inside an enclosure the emitter VCI molecules fill the air, migrating from the emitter, through the air space and onto the exposed metal surface.

Daubrite VCI emitter pad features

Compatible with a variety of metals including steel, copper, zinc and other multi-metal alloys

- Thin, lightweight & non-intrusive disks are designed to fit as discretely as possible in tight or enclosed spaces.

- Strong self adhesive tape attaches easily to metal containers, walls etc.

- Does not require special handling measures, safe and easy to use.

- A dry & clean corrosion prevention method.

- Can protect up to 24 months when used in a dry, ambient environment.

- Compatible with a range of other Daubert Cromwell products including the Metalguard VCI Bags and Daubert VCI paper.

Where can these VCI emitting products be used

A product as versatile as this is constantly discovering new uses for itself but we have consistently seen Daubrite pads used with:

- Metal junction boxes & control panels.

- Telecoms and electrical equipment.

- Mechanical instruments and controls.

- Utility & tool boxes.

- Included in export crating with other Daubert products such as 3D gusset/box bags for an optimal flexible packaging solution.

Please note – always wear gloves when handling metal parts. Ensure parts are clean and free from an fingerprints before positioning emitters.

Try to ensure cleaned products are packaged as quickly as possible. Where possible ensure the metal part to be protected is no more than 12″ from the surface of the VCI emitter.

The closer VCI emitting products are to the metal surface to be protected the better the corrosion protection.

Use at least 1 x Daubrite 5 Disk emitter for every 5 cubic feet of void space. The Daubrite 10 disk emitter can reach up 10 cubic feet of void space.