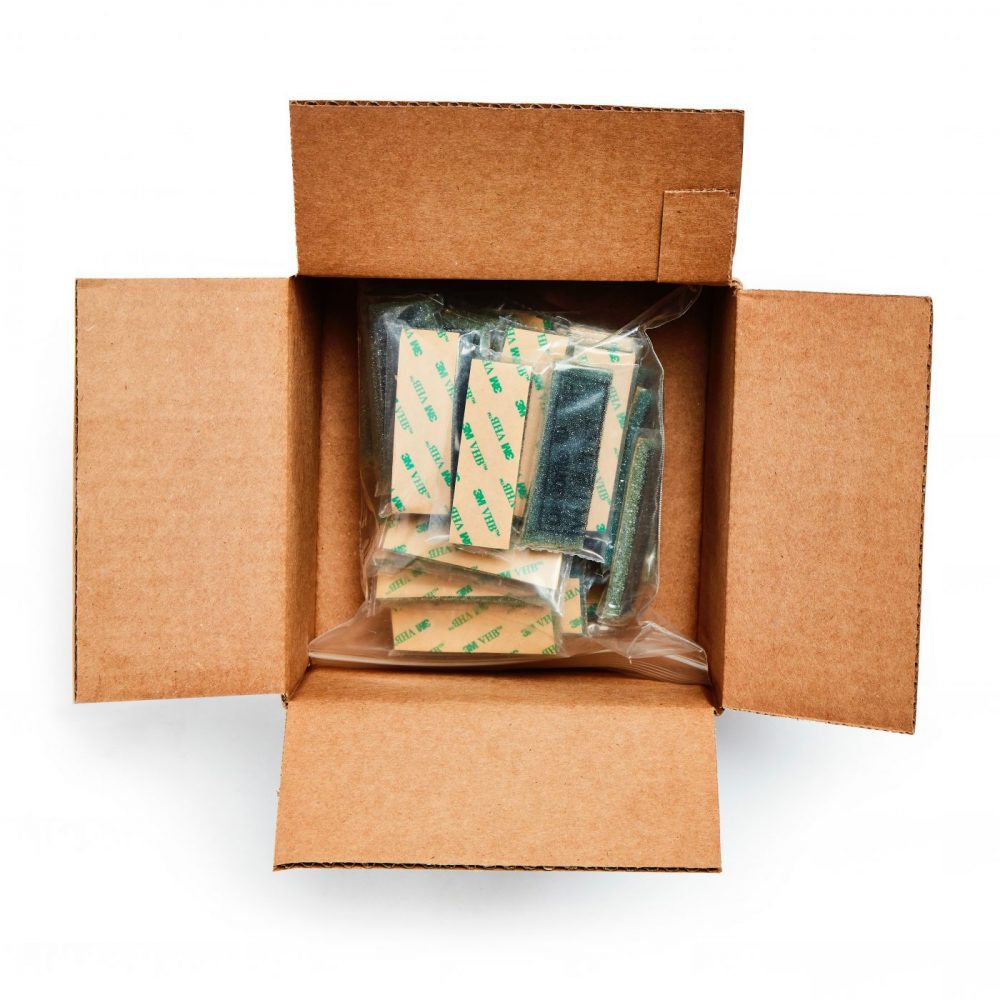

Daubrite® Foam & 3F Verion w/ 3M™ VHB™ Tape | VCI Foam Emitter Pads

Daubrite® Foam & 3F Verion w/ 3M™ VHB™ Tape | VCI Foam Emitter Pads

Stock TBD

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Daubrite® VCI Foam Emitter Pads are ideal for use in confined and enclosed spaces.

Available as regular foam pieces for manual insertion/scattering or as the ‘3F’ self adhesive version that comes fitted with 3M VHB Tape.

Daubrite VCI foam emitter pads are an open cell foam containing the market leading Daubert Cromwell corrosion inhibitor formula to protect sensitive metals in enclosed spaces.

Each individual Daubrite VCI foam emitter pads are each cut to 1″ x 3″ x 0.25″, available as either plain foam to place loose or with a 3M VHB double sided tape to attach.

Each piece is designed to protect metal surfaces inside up to 1 cubic foot (0.028m³) of enclosed space for up to 2 years. These VCI emitter pads offer the best protection for both ferrous & non-ferrous metals.

Applications For Daubrite® VCI Foam Emitter Pads

These VCI foam pads provide outstanding corrosion protection in –

- Electrical Panels

- Circuit Breakers

- Utility Boxes

- Telecoms equipment

- Electronic Parts & Components

- Control Boxes

- Switches and Relays

- Firearms Storage Cabinets

What metals are protected by Daubrite Foam?

- Cast iron and mild carbon steel – provides complete contact and vapor phase protection

- Aluminium – passive, requires testing for compatibility.

- Zinc & zinc galvanised steel – provides complete contact and vapour phase protection.

- Copper – provides complete contact and vapour phase protection.

- Brass – Fully protected.

- Bronze – Fully protected.

- Silver – possible protection, compatibility testing required.

For category A metals including zinc, cadium & nickel these metals are vulnerable to contact corrosion sensitivity with other VCI inhibitor coatings and chemicals. However they are still protected in the vapour phase.

Category B metals comprise of lead, antimony, solder, magnesium and its alloys.

Daubrite foam emitter pads have a shelf life of up to 24 months when stored in original package, avoiding high temperatures and humidity.

For larger areas and spaces in need of VCI protection consider our larger Daubrite 5 & 10 emitter pads for further reaching protection.

These Daubrite foam pads work well with other VCI Packaging products for a complete solution. These include MetalGuard VCI Bags and Master-shield VCI Paper.

3M™ and VHB™ are registered trademarks of 3M Corporation, all rights reserved.

Product Specifications

| Call |