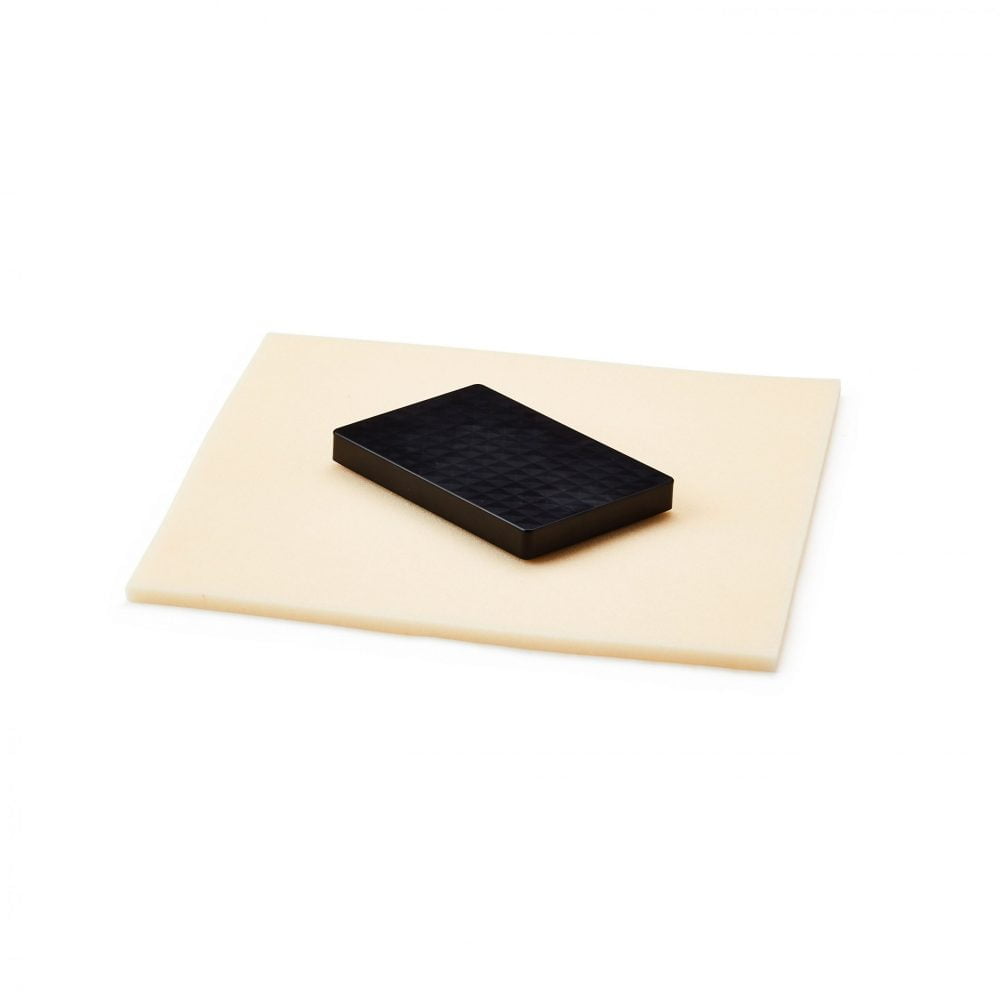

Cortec VpCI® 132 VCI Foam / Anti Static Action Foam 10 x 10″ (25 x 25cm Individual Units)

Cortec VpCI® 132 VCI Foam / Anti Static Action Foam 10 x 10″ (25 x 25cm Individual Units)

50 in stock

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Cortec VpCI® 132 ESD Foam Packaging are high performance self adhesive foam inserts that provide multifaceted protection for sensitive metals and electronics travelling through the supply chain.

The dual action of VpCI Corrosion Inhibitors and Desiccant compliment the anti static action to give long term protection from the usual environmental hazards that lead to defect product. Available as standard pre-cut sizes bespoke custom shapes are available upon request.

We offer creative solutions for custom ESD foam inserts. As the Cortec® Master Distributor we supply both pre-cut and bespoke ESD Foam material.

Our solutions focus on the VpCI 130® series of custom ESD Foam Inserts. This patented formula contains a multifunctional VpCI® (Vapour Phase Corrosion Inhibitors) that is impregnated into the foam carrier itself. Each insert utilises the dual action of VpCI & Desiccant to give market leading corrosion and antistatic protection for your sensitive goods.

Using VpCI emitter products essential eliminates the need for legacy rust prevention solutions. Parts are always protected and ready to use, with no manual coating removal or messy degreasing required.

VpCI 130 solutions can drastically decrease your bottom line, resulting in significant overall savings on both weight and labour.

VpCI molecules keep working into the long term. They are effective against the usual atmospheric hazards including humidity, condensation, aggressive atmospheres , marine air and residual impurities that occur during the manufacturing process.

Custom ESD Foam Inserts With Enhanced VpCI® Protection

The polymer matrix of each piece of cut foam (either pre-cut or custom) is impregnated with the VpCI formula throughout. Suitable for the protection of all metals, both ferrous and non ferrous, VpCI does not effect or alter the physical or chemical properties of electronic components. This makes any foam in the VpCI 130 series highly suitable for the protection of Printed Circuit Boards (PCB‘s).

The VpCI 130 range has a shelf life of 2 years if kept in its original packaging. To maintain strength unused foam should be kept sealed in plastic bags. Consider using one of our heat sealer machines.

Features of VpCI® VCI Foam

Cortec VpCI 130 foams are impregnated with the VpCI corrosion inhibitor formula throughout the foams polymeric substrate. The 130 series is a multi metal VCI foam meaning it is compatible with both ferrous and non-ferrous metals alike. Alloys such as copper, brass, aluminium, solder, silver and zinc also work well with the 130 range.

Metals protected include:

- Aluminium

- Carbon Steels

- Brass

- Solder

- Galvanised Steel

- Silver

- Copper & Zinc

- Benefits

Benefits

All VpCI 130 foam products are free from nitrates and chromates. The high performance, patented VpCI® formula provides fast acting, continuous protection that is easy to apply and use. VpCI has been tested extensively in the harsh condition & climates that goods travelling through the supply chain may encounter. This makes the VpCI series very suitable for overseas export packaging, particular when goods may in an aggressive environment.

Each product contains approximately 10 x times the amount of active VpCI® formula per square foot (or meter) of substrate than that of other corrosion prevention solutions including VCI paper and other anti corrosion wrapping paper products.

The VpCI itself works in a unique way with this product. High and low pressure VpCI molecules afford long term protection as an export packaging material. This makes these products ideal for objects and products with larger surface areas such as plywood boxes and larger oceangoing containers.

Often VCI Foam products are combined with other products such as VpCI 126 Shrink Film and other VCI Emitters to create an optimal packaging solution.

VpCI 130 foams have been tested to MIL PRF 26514G, Type 3, Class II.

How to Apply

VpCI 130 foams form a strong layer of protection as a standalone product, but please ensure there are no barriers or obstructions between the VpCI molecules and the metal surface itself. Where the foam insert is positioned/placed is not important as the VpCI molecules essentially evaporate and share the same air space as the metal within the enclosure.

This product is not intended to be used as standalone cushioning. Where this is key consider the range of VpCI 150 & 170 adhesive foam tapes.

Of our standard pre-cut VCI foam inserts the VpCI 132 featured on this page provides the largest protection radius. If you require a smaller substrate consider either the VpCI 131 antistatic foam or the VpCI 133 .

VpCI 130® products have a shelf life of 2 years when sealed in their original packaging. To maintain the strength of the active molecules the foam should be kept sealed in plastic bags between uses.

Product Specifications (.PDF)