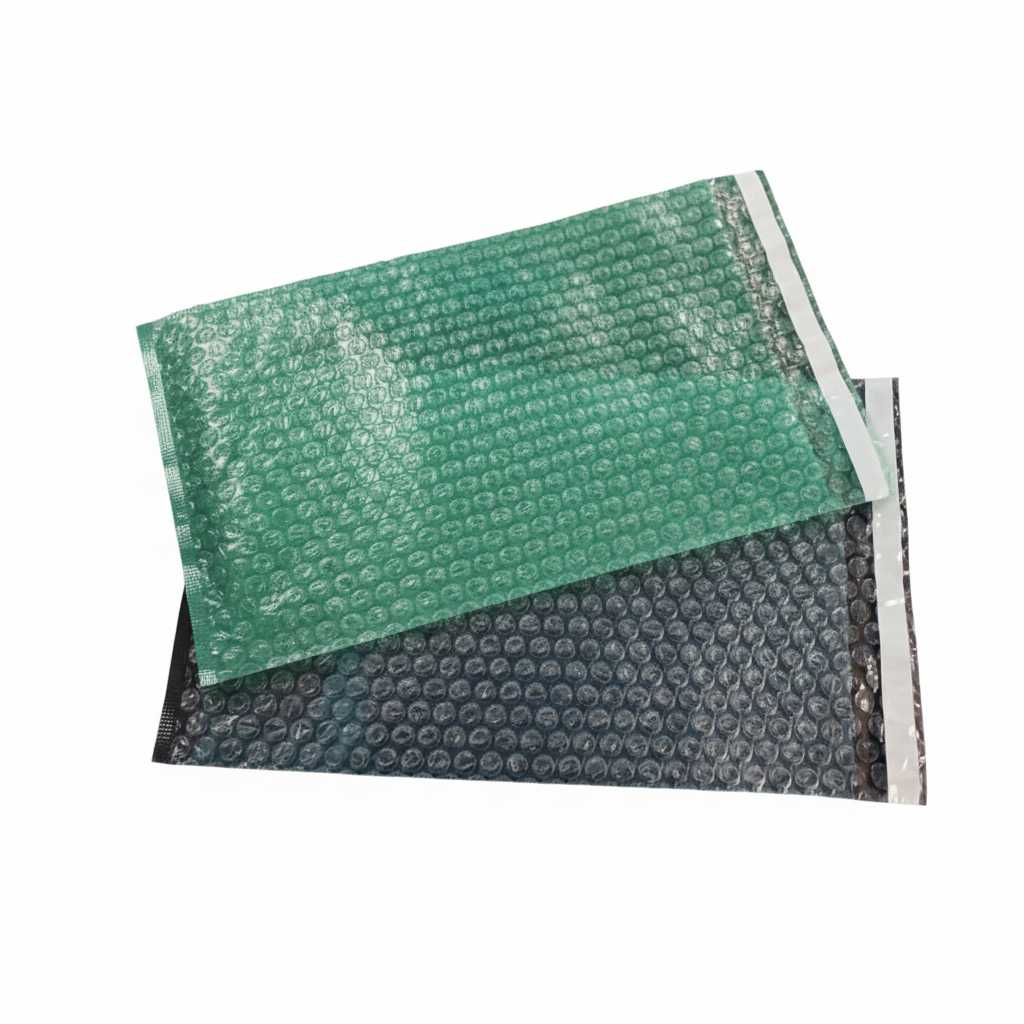

Cortec EcoSonic® ESD Self-Seal Bubble Bags powered by Nano VpCI

Cortec EcoSonic® ESD Self-Seal Bubble Bags powered by Nano VpCI

Couldn't load pickup availability

Cortec EcoSonic® ESD Self-Seal Bubble bags are powered by Nano VpCI®.

With the power of corrosion inhibitor, the bubble bags cushion and protect your sensitive electronic equipment from physical damage, corrosion, and triboelectric charge accumulation. They also come in a non-ESD variant.

EcoSonic® ESD Self-Seal Bubble Bags operate by saturating the confined airspace with vapor phase corrosion inhibitors, which build a protective molecular coating on all sensitive metals without leaving any visible film or residue. The bubbles are used as padding, dunnage, and void fill material.

EcoSonic® ESD Self-Seal Bubble Bags are #4 recyclable. *

* Remove adhesive strip before recycling.

Packaging & Storage of Self-Seal Bubble Bags

Bag sizes are available in10 x 12 in (25.4 x 30.5 cm) and 6 x 8 in (15.2 x 20.3 cm).

For optimum product performance, store the bubble bags in their original packaging. Keep them indoors at 40-100 °F (4-38 °C) and away from direct sunlight.

Shelf life: 1 year

Features

- Simple usage.

- Cushions your items and at the same time protects them from corrosion.

- Does not interfere with subsequent processing (i.e., cleaning, soldering, welding, painting).

- Does not adversely affect elastomers, plastic (lexane), optics, and other non-metallics.

- Meets corrosion protection standard (NACE TM0208-2018).

- Meets another standard on corrosion protection (German TL-8135-002).

Benefits

- Protects sensitive objects.

- Safeguards metal, steel, and alloys against corrosion.

- Prevents triboelectric charge creation (ESD version only).

Metals Protected

- Stainless Steel.

- Carbon Steel.

- Copper.

- Aluminum.

- Brass.

- Silver.

Application

Put your item inside the bubble bag. Remove adhesive white strip and fold the top to seal.

Technical Properties

ESD properties apply to the inside of the bag:

- Surface Resistance: <1x1011.

- •Static Decay Rate: <2 seconds.

Property |

|

Test Method |

Units |

EcoSonic® ESD Bubble Film |

Cor-Pak® VpCI® Self- Seal Bubble Bags |

Caliper |

ASTM D6988 |

mil (µm) |

5.00 |

5.00 |

|

Breaking Factor |

MD |

ASTM D882- 02 |

lbs/in (N/m) |

19.02 (3330.91) |

14.57 (2551.60) |

CD |

17.03 (2982.41) |

15.99 (2800.28) |

|||

Tensile Strength at Break |

MD |

ASTM D882- 02 |

psi (kPa) |

3804.00 (26,227.66) |

2913.00 (20,084.43) |

CD |

3406.00 (23,483.54) |

3197.00 (22,042.54) |

|||

Elongation at Break |

MD |

ASTM D882- 02 |

% |

859.52 |

557.89 |

CD |

921.48 |

888.91 |

|||

Yield Strength |

MD |

ASTM D882- 02 |

psi (kPa) |

1737.44 (11,979.23) |

2129.98 (14,685.70) |

CD |

1602.83 (11,051.12) |

1547.79 (10,671.64) |

|||

Tear Strength |

MD |

ASTM D1922-06a |

gram force (lbf) |

1651.20 (3.64) |

1587.20 (3.50) |

CD |

2393.60 (5.28) |

1894.00 (4.18) |

|||

Dart Drop Impact Resistance |

ASTM D1709- 04Test Method A |

grams (lbs) |

562.20 (1.24) |

513.70 (1.13) |

|

Puncture Resistance |

Outside |

MIL-STD -3010, TM 2065 |

lbf (gf) |

6.80 (2893.92) |

7.21 (3270.40) |

Inside |

7.49 (3397.41) |

8.12 (3683.17) |

|||

Seal Strength |

ASTM F88-99 |

lbs/in (N/m) |

8.65 (1514.85) |

9.45 (1654.95) |

|

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly makes Cortec EcoSonic ESD Self-Seal Bubble Bags stand out from regular bubble wrap?

These bags go beyond simple cushioning by combining three crucial elements: they protect your sensitive electronics from physical damage with the bubble layer, prevent corrosion on metal components thanks to Nano VpCI® (Vapor phase Corrosion Inhibitor) technology, and safeguard against electrostatic discharge (ESD) which can seriously harm delicate circuits. It’s a triple threat solution for peace of mind.

• How does the "Nano VpCI®" technology actually work inside these bags to prevent corrosion?

The Nano VpCI® technology works by releasing tiny, invisible vapor molecules into the air inside the sealed bag. These molecules then form a protective, molecular layer on all exposed metal surfaces. This ultra-thin film actively repels moisture, oxygen, and other corrosive elements, safeguarding your items from rust and other forms of degradation without leaving any visible residue.

• Beyond physical bumps, what specific types of damage do these bags protect sensitive electronics from?

These bags offer comprehensive protection, guarding against physical damage from impacts, corrosion on metal components (like rust or tarnish), and critically, triboelectric charge accumulation, which is the static electricity that can harm sensitive electronic parts.

• Can these bags protect various types of metals, or are they limited to certain ones?

The Nano VpCI® technology in these bags is designed to protect a wide range of metals, including stainless steel, carbon steel, copper, aluminum, brass, and silver, making them quite versatile for diverse electronic components.

• Do these bags leave any kind of residue or film on the items after they've been stored inside?

No, a significant benefit of these bags is that the protective molecular coating formed by the VpCI® technology does not leave behind any visible film or residue on your sensitive metals. This means your items are ready for use immediately upon removal.

Relevant products you may want to consider:

• Are these EcoSonic bags also designed with environmental considerations in mind?

Yes, a key aspect of these bags is their recyclability. They are classified as #4 recyclable, which helps in reducing environmental impact compared to some traditional packaging methods.

• How do these bags prevent static electricity build-up, and why is that important for electronics?

The ESD properties of these bags prevent the generation of triboelectric charges. This is vital for electronics because static discharge can cause irreparable damage to sensitive components, leading to malfunction or complete failure, even if the static shock isn't felt by a human.

• What makes the self-seal feature of these bags convenient for users?

The self-seal strip integrated into the bag makes packaging incredibly easy and efficient. You simply place your item inside, peel off the white adhesive strip, and fold the top over to create a secure seal, eliminating the need for additional sealing equipment.

• Are these bags suitable for items that might undergo further manufacturing processes like soldering or welding?

Absolutely. The corrosion inhibitors used in these bags are designed not to interfere with subsequent processing steps such as cleaning, soldering, or welding, which is a big advantage for manufacturers.

• Do these bags negatively affect non-metallic parts of an electronic device, such as plastics or optics?

No, the corrosion inhibitors in these EcoSonic bags are formulated to have no adverse effects on non-metallic materials like elastomers, various plastics (including Lexan), or optical components, ensuring holistic protection for your electronic assemblies.

Relevant products you may want to consider:

• What specific types of electronic components are ideally suited for protection with these bags?

These bags are perfect for safeguarding a variety of sensitive electronic components, including hard drives, processors, video graphics cards/boards, memory sticks/modules, networking cards/boards, and other circuit boards.

• Can these bags be used for protecting electronics during long-distance shipping, especially through varied climates?

They are explicitly designed for this purpose. The bags tackle the challenges of unpredictable and extreme environments during global shipment, protecting against the condensation and corrosion that can occur due to fluctuating temperatures and humidity.

• Are these bags useful for simply storing electronic parts in a warehouse, or are they primarily for transit?

While excellent for transit, they are equally effective for storage. The VpCI® technology creates a protected environment within the bag, which is particularly beneficial in humid climates where climate-controlled warehousing might otherwise be necessary and expensive.

• Could these bags be used for protecting spare parts or smaller electronic assemblies?

Yes, given the available sizes, they are well-suited for protecting smaller components and spare parts, ensuring they remain in pristine condition until needed.

• If I have an electronic item that contains multiple types of metals, will this bag protect all of them simultaneously?

Yes, the Nano VpCI® technology is designed to protect multi-metal assemblies. It forms a protective layer on all susceptible metal types within the enclosed space, addressing the complexity often found in electronic devices.

Relevant products you may want to consider:

• How do I actually use these EcoSonic ESD Self-Seal Bubble Bags to protect my items?

It’s quite straightforward: simply place your electronic item inside the bubble bag, peel off the white adhesive strip that covers the self-seal, and then fold the top flap of the bag over to firmly seal it.

• What are the available sizes for these self-seal bubble bags?

Currently, these bags are available in two common sizes: 6 x 8 inches (15.2 x 20.3 cm) and 10 x 12 inches (25.4 x 30.5 cm), offering options for different component dimensions.

• What are the best conditions to store these bubble bags in before I use them?

For optimal performance and to maintain their shelf life, you should store the bubble bags in their original packaging, indoors, away from direct sunlight, and within a temperature range of 40-100 °F (4-38 °C).

• How long can I expect these bags to remain effective, in terms of their shelf life?

The recommended shelf life for these EcoSonic ESD Self-Seal Bubble Bags is generally one year when stored under the optimal conditions mentioned.

• Can these bags be reused after they've been opened and an item removed?

While the VpCI® protection relies on a sealed environment, if the bag is kept clean, dry, and undamaged, and the seal is still effective, some reusability might be possible, but it's important to consider if the VpCI effectiveness has been maintained. The anti-static properties are permanent as long as the bags are in use.

Relevant products you may want to consider:

• What happens if I accidentally open the bag after sealing it? Does the corrosion protection disappear instantly?

The VpCI® technology provides continuous protection as long as the items remain in a relatively enclosed environment. While opening the bag will allow some VpCI® molecules to dissipate, the protective layer on the metal will remain for a period. For best long-term protection, it's ideal to keep the bag sealed.

• How do these bags compare to traditional anti-corrosion methods like using oils or desiccants?

These bags offer a cleaner and more efficient solution than traditional methods. They eliminate the need for messy oils and greases, and unlike desiccants, they actively prevent corrosion rather than just absorbing moisture, often allowing immediate use of the protected item without cleaning.

• Is the ESD protection permanent in these bags, or does it wear off over time or with humidity?

The EcoSonic ESD Self-Seal Bubble Bags incorporate permanent anti-static properties. This means they are designed to immediately reduce or eliminate static buildup as long as they are in use, and this protection is independent of humidity levels.

• Do these bags meet any industry standards for corrosion protection or ESD?

Yes, these bags meet rigorous standards, including the corrosion protection standard NACE TM0208-2018, and the German TL-8135-002, indicating their reliability and effectiveness in various industrial contexts.

• What is the material composition of these bubble bags?

While the exact proprietary blend isn't fully detailed, these bags are made with polyethylene (PE), a common plastic for anti-static bags, and are infused with the Nano VpCI® technology. They also incorporate cushioning bubbles for physical protection.

Relevant products you may want to consider:

• How do the Nano VpCI® bubble bags contribute to waste reduction in the electronics industry?

• Are there different versions of this product available, for example, without ESD protection?

Yes, while the focus here is on the ESD version, EcoSonic bubble bags are also available in a non-ESD variant for applications where static protection isn't a primary concern but corrosion and physical protection are still needed.

• How does the Nano VpCI® technology create a "Faraday cage" effect for electronics, if at all?

While VpCI® technology primarily focuses on corrosion inhibition through vapor release, the ESD-safe nature of the bag material helps to dissipate static charges, preventing the harmful effects of electrostatic discharge. It complements ESD shielding but doesn't inherently create a Faraday cage, which typically requires a conductive enclosure.

• Can I customize the sizes of these bags for my specific packaging needs?

The readily available sizes are 6x8 inches and 10x12 inches, but for larger scale industrial needs, custom sizes might be available directly from Cortec or its distributors, so it's always worth inquiring if your requirements fall outside the standard offerings.

• Why is combining corrosion protection with ESD and cushioning in one bag considered a "breakthrough" for the electronics industry?

It's a breakthrough because it simplifies the packaging process while offering comprehensive protection against the three primary threats to electronics: physical impact, static discharge, and corrosion. This multi-functional approach increases efficiency, reduces the need for multiple packaging materials, and ensures higher product integrity upon arrival or after storage, ultimately saving time and costs for businesses.