Cortec EcoSonic® ESD 3D Hoods powered by Nano-VpCI®

Cortec EcoSonic® ESD 3D Hoods powered by Nano-VpCI®

Couldn't load pickup availability

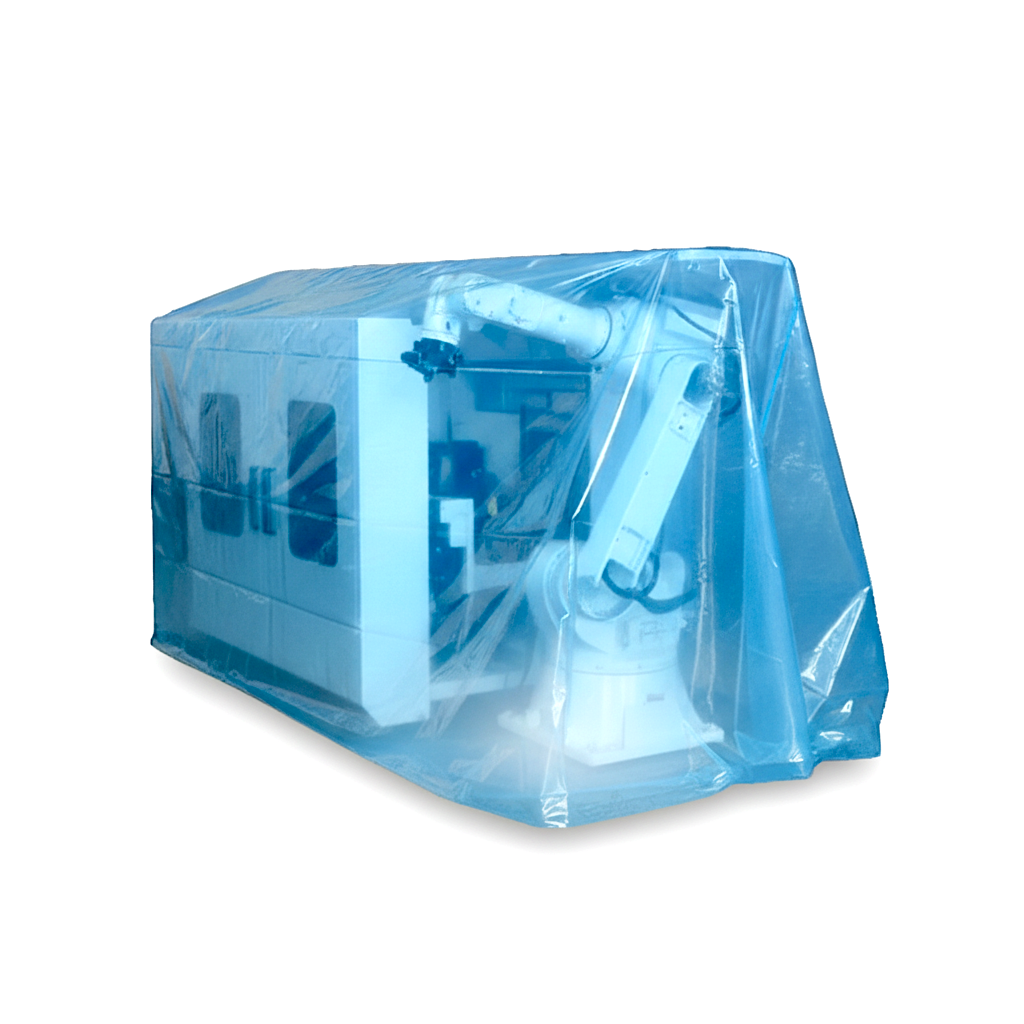

Nano-VpCI® powers EcoSonic® ESD 3D Hoods. This is a solution for protecting metal products from corrosion while offering numerous advantages.

- Superior Corrosion Protection: EcoSonic® ESD 3D Hoods provide unparalleled protection against all forms of corrosion. This includes oxidation, rust, stains, tarnish, and white rusts. With a corrosion resistance duration of up to 2 years (1 year for ESD protection), your valuable metal products are safeguarded for an extended period.

- Environmentally Friendly: Unlike traditional rust protectors such as desiccants and oils, VpCI® packaging doesn’t need a degreaser or removal of coating. This saves both time and resources. Additionally, EcoSonic® ESD 3D Hoods are non-toxic and recyclable, ensuring eco-conscious and sustainable practices.

- Transparent Design: The hoods are transparent, allowing for easy identification of parts without the need to unwrap them. This feature streamlines inventory management and enhances operational efficiency.

- Antistatic Properties: EcoSonic® ESD 3D Hoods are equipped with antistatic properties, significantly reducing or eliminating static buildup during their use, regardless of humidity levels. This ensures that your sensitive electronic components and devices remain protected from electrostatic discharge.

- Customisable Resins: The hoods are produced using a wide range of advanced resins, offering tailored solutions to meet specific requirements. Whether you need an improved tear or puncture resistance, custom blends are available to suit your needs perfectly.

3d Hoods Features

- Nano-VpCI® Technology: The incorporation of Nano-VpCI® ensures powerful corrosion inhibition at the molecular level, providing a robust and long-lasting protective barrier for your metal products.

- Easy to Use: EcoSonic® ESD 3D Hoods are designed for immediate use without the need for additional preparation. Simply place your metal items inside the hoods, and they are instantly shielded from corrosive elements.

- Diverse Size Protection: The hoods are suitable for protecting metal objects of various sizes, making them versatile and adaptable to different applications. Whether you have small electronic components or large industrial parts, these hoods have got you covered.

- Extended Shelf Life: With the capability to extend the shelf life of your metal products, EcoSonic® ESD 3D Hoods powered by Nano-VpCI® reduce the need for frequent inspections, rework, and replacements, resulting in cost savings and increased productivity.

High Level of Corrosion Protection

This innovative packaging ensures that your components remain shielded from the harshest environmental elements, such as condensation, excessive humidity, Industrial atmospheres, salt, moisture, and even metal corrosion between dissimilar types.

The secret lies in the NanoVpCI® molecules. These molecules are released into the enclosed package and create a vaporised shield that envelops the metal surfaces. They condense on the parts and penetrate every part of a surface. With this comprehensive coverage, your products are safeguarded both on the outside and within.

Whether stored for extended periods or shipped domestically or overseas, rest assured that this VpCI® technology protects your product completely. This solution virtually eliminates any risk of corrosion-related issues.

As a testament to its effectiveness, VpCI films have earned their place as one of the best-selling anticorrosion PE films globally. These have outperformed standard and internal corrosion test methods, proving their superiority in corrosion protection.

Recyclable & Environmentally Conscious

We are thrilled to announce the groundbreaking EcoSonic® ESD 3D Hoods powered by Nano-VpCI®, a product that has earned remarkable recognition for its commitment to sustainability. These hoods have received full approval from a renowned institute, validating their eco-friendly attributes and responsible packaging. Moreover, Cortec®, the visionary company behind EcoSonic® ESD 3D Hoods, is unwavering in its dedication to crafting environmentally conscious solutions.

One of the key highlights of EcoSonic® ESD 3D Hoods is the innovative use of 20% recycled content in their manufacturing process. This progressive approach further elevates the product's environmental credentials. By actively promoting the reuse of materials, Cortec® is contributing to the preservation of the planet's precious resources.

Not only are these hoods leading the charge in recyclability, but they also harness the power of Nano-VpCI® technology. This cutting-edge solution utilises nanotechnology to provide unparalleled protection against corrosion and extends the product's lifespan. It reduces the need for frequent replacements and reduces waste.

Product Specifications (.PDF)

| Call |

Frequently Asked Questions

• What exactly are Cortec EcoSonic ESD 3D Hoods and what makes them so special?

These aren't just your average protective covers; Cortec EcoSonic ESD 3D Hoods are advanced, high-tech packaging solutions. What sets them apart is their unique combination of the latest film technology with Cortec's patented Nano-VpCI® (Vapor phase Corrosion Inhibitor) technology, providing comprehensive protection for all sorts of metal products.

• How do these hoods actually protect against rust and other forms of corrosion?

It's quite clever, really. When you seal your metal product inside a Cortec EcoSonic ESD 3D Hood, the Nano-VpCI® molecules within the film vaporize and then condense onto all exposed metal surfaces inside the package. This creates a microscopic, protective molecular layer that actively defends against various forms of corrosion, including rust, tarnish, stains, white rust, and even oxidation.

• Beyond corrosion, how do these hoods address the issue of electrostatic discharge (ESD)?

That's the "ESD" part of their name! These hoods are specifically designed with permanent anti-static properties. This means they immediately reduce or completely eliminate static buildup as long as your items are enclosed within the hood, regardless of the surrounding humidity levels. It's crucial for safeguarding sensitive electronic components from static damage.

• Are these hoods a replacement for traditional rust preventatives like oils or desiccants?

Absolutely, they're designed to be a direct and much more convenient replacement. Instead of dealing with messy oils or unreliable desiccants, the VpCI® technology in these hoods provides clean, dry protection. This also means you don't have to go through the hassle of degreasing or cleaning off coatings when your product is ready for use, saving you a significant amount of time and effort.

• Can you explain a bit more about the "Nano-VpCI®" part of the name? What does "Nano" signify here?

The "Nano" in Nano-VpCI® refers to the cutting-edge, nano-sized particles of the Vapor phase Corrosion Inhibitor technology. These tiny molecules are what allow the VpCIs to readily vaporize and spread throughout the enclosed space, effectively reaching and protecting even the most intricate and hard-to-reach surfaces of your metal items.

Relevant products you may want to consider:

• What types of metal products can benefit from being protected by Cortec EcoSonic ESD 3D Hoods?

These hoods are incredibly versatile and offer multi-metal protection. They are suitable for safeguarding a wide range of metals, including ferrous metals like steel, as well as non-ferrous metals such as copper and its alloys, aluminum and its alloys, brass, solder, and nickel.

• Can I use these hoods for long-term storage or just for shipping?

They are ideal for both! Cortec EcoSonic ESD 3D Hoods are engineered to provide effective corrosion protection for up to two years, with the ESD protection lasting for one year, making them perfect for both short-term transit and extended storage of valuable components.

• How do I properly apply or use one of these 3D hoods to ensure maximum protection?

It's designed to be straightforward. First, ensure your metal parts are clean and dry before packaging. Then, simply place your item inside the 3D hood and seal it to create an enclosed environment. The VpCI® will then begin to vaporize and protect your components. For the best performance, it's generally recommended to keep the hood as close to the item's surface as practical, without any barriers in between.

• Are these hoods suitable for delicate electronic components like printed circuit boards (PCBs) or integrated circuits?

Yes, absolutely! They are specifically formulated to protect static-sensitive multi-metal items, making them an excellent choice for integrated circuits, printed circuit boards, various PCB components, telecommunications equipment, electrical panels, and even batteries. The film doesn't interfere with the electrical or physical properties of these sensitive items.

• Can I use these hoods if my products are going to be exposed to harsh environments, like high humidity or industrial atmospheres?

Indeed. Metal parts packaged within these hoods receive continuous protection against a variety of aggressive elements, including salt, excessive humidity, condensation, moisture, and challenging industrial atmospheres. They also help prevent dissimilar metal corrosion, which can be a significant concern in varied environments.

Relevant products you may want to consider:

• Do these hoods leave any residue on the metal parts once the product is removed?

One of the great advantages of VpCI® technology is that it forms an invisible molecular layer that does not interfere with the physical or chemical properties of electronic components. This means there's no residue left behind, so your products can be used immediately without any cleaning or degreasing.

• Are there any considerations for sealing the hoods to ensure optimal performance?

While the VpCI® vaporizes to protect, ensuring a good seal will help maintain the enclosed environment and the concentration of the VpCI® for longer-lasting and more effective protection. Heat sealing is often recommended for the most secure closure.

• Can these hoods be used for international shipping where items might encounter diverse climates?

They are certainly well-suited for international shipments. Their robust protection against a wide range of corrosive elements, including fluctuating temperatures and humidity levels, makes them a reliable choice for safeguarding goods during long transit times across different climates.

• Is there a specific orientation for placing items inside the hood for best results?

While the VpCI® vaporizes to reach all surfaces, generally, placing the item centrally within the hood and ensuring adequate space for the vapor to circulate freely around the object will contribute to optimal protection.

• Are these hoods compatible with automatic packaging equipment?

While the product description focuses on the material's properties, Cortec generally designs its VpCI® films and bags to be adaptable for various packaging methods, including manual and automated processes. For specific machinery compatibility, it's always best to consult with the supplier.

Relevant products you may want to consider:

• What is the typical shelf life of an unused Cortec EcoSonic ESD 3D Hood?

When stored properly, these hoods have a good shelf life. You can expect the corrosion protection to remain effective for up to two years, with the ESD protection maintaining its properties for one year.

• How should I store these hoods to ensure they remain effective for their stated shelf life?

To ensure they perform at their best, it's important to store the hoods in their original packaging, indoors, and away from direct sunlight. The ideal temperature range for storage is typically between 4-38 °C (40-100 °F).

• Are Cortec EcoSonic ESD 3D Hoods available in different sizes or can they be customized?

Yes, these films and bags are typically available in various custom sizes and formats. This flexibility allows them to fit a wide range of electronics packaging needs, from smaller components to larger equipment.

• What are the common thicknesses for the film used in these hoods?

The film thickness for EcoSonic VpCI®-125 HP Permanent ESD Films and Bags usually ranges from 2-6 mils (50-150 microns), providing robust and reliable protection.

• Do these hoods contain any harmful or hazardous chemicals?

A key advantage of Cortec products, including these hoods, is their focus on safety. They are designed to be safe for use and typically do not contain harmful Prop 65 ingredients, nitrites, phosphates, silicates, or other hazardous compounds.

Relevant products you may want to consider:

• Does the EcoSonic ESD 3D Hood affect the solderability of PCBs or other electronic parts?

No, it does not. The protective molecular layer formed by the VpCI® technology is designed not to interfere with the physical or chemical properties of electronic components, which includes their solderability. This ensures your components are ready for assembly right out of the package.

• Can I see through these hoods, or are they opaque?

Cortec VpCI® 3D Bags are generally transparent, which is a really helpful feature because it allows for easy identification of the parts contained within, even when they're sealed.

• Do these hoods offer protection for components against physical damage or just corrosion and static?

While their primary function is to protect against corrosion and electrostatic discharge, the film itself offers a degree of barrier protection against dust, dirt, and moisture ingress. However, for significant physical impact protection, additional cushioning or outer packaging would be necessary.

• Are there any specific certifications or standards that these hoods adhere to for ESD or corrosion protection?

Yes, Cortec EcoSonic ESD products often conform to important industry standards. For instance, the static dissipative film and bags typically meet the surface resistivity and static decay requirements of MIL-PRF-81705D (Static Dissipative Packaging Materials) and may also conform to MIL-PRF-3420H for vapor inhibiting ability.

• Is the anti-static protection in these hoods dependent on humidity, unlike some other ESD materials?

A significant benefit of these hoods is that their permanent anti-static properties work independently of the presence of humidity. This means they consistently reduce or eliminate static buildup, even in very dry environments where other anti-static solutions might fail.

Relevant products you may want to consider:

• Are Cortec EcoSonic ESD 3D Hoods environmentally friendly or recyclable?

Cortec is committed to sustainability, and many of their VpCI® packaging solutions, including variations of 3D bags, are fully recyclable. Some versions are even developed with post-consumer recycled content or are biodegradable and compostable, aiming to minimize the ecological footprint.

• Do these hoods reduce overall packaging waste compared to traditional methods?

By combining corrosion protection and ESD safety into one packaging solution, and eliminating the need for additional rust preventatives like oils and desiccants, these hoods can definitely help streamline packaging and potentially reduce the amount of different materials used, contributing to less waste.

• Is it possible to reuse these Cortec EcoSonic ESD 3D Hoods?

While some VpCI® films can offer self-replenishing protection even if opened and re-sealed, the specific reuse capability of these 3D hoods would depend on how well the integrity of the seal can be maintained and the duration of previous use. For optimal performance and certainty, particularly with sensitive electronics, using a fresh hood for each long-term application is generally recommended. However, their recyclable nature is a strong environmental benefit.

• How do these hoods contribute to cost savings for businesses?

The cost savings are multi-faceted. By eliminating the need for degreasing or coating removal, they save on labor time and associated expenses. They also reduce the need for multiple packaging materials, and critically, by preventing corrosion and ESD damage, they significantly reduce costly product rejections, repairs, or replacements, leading to better product reliability and customer satisfaction.

• What is the typical lead time if I need custom sizes or a large quantity of these hoods?

Lead times can vary depending on the specific custom requirements and the volume ordered. It's always best to discuss your particular needs directly with Valdamark Direct, as they can provide the most accurate information on production and delivery schedules for custom or bulk orders.

Relevant products you may want to consider: