Cortec CorrNetting Protective Tubular Netting

Cortec CorrNetting Protective Tubular Netting

Couldn't load pickup availability

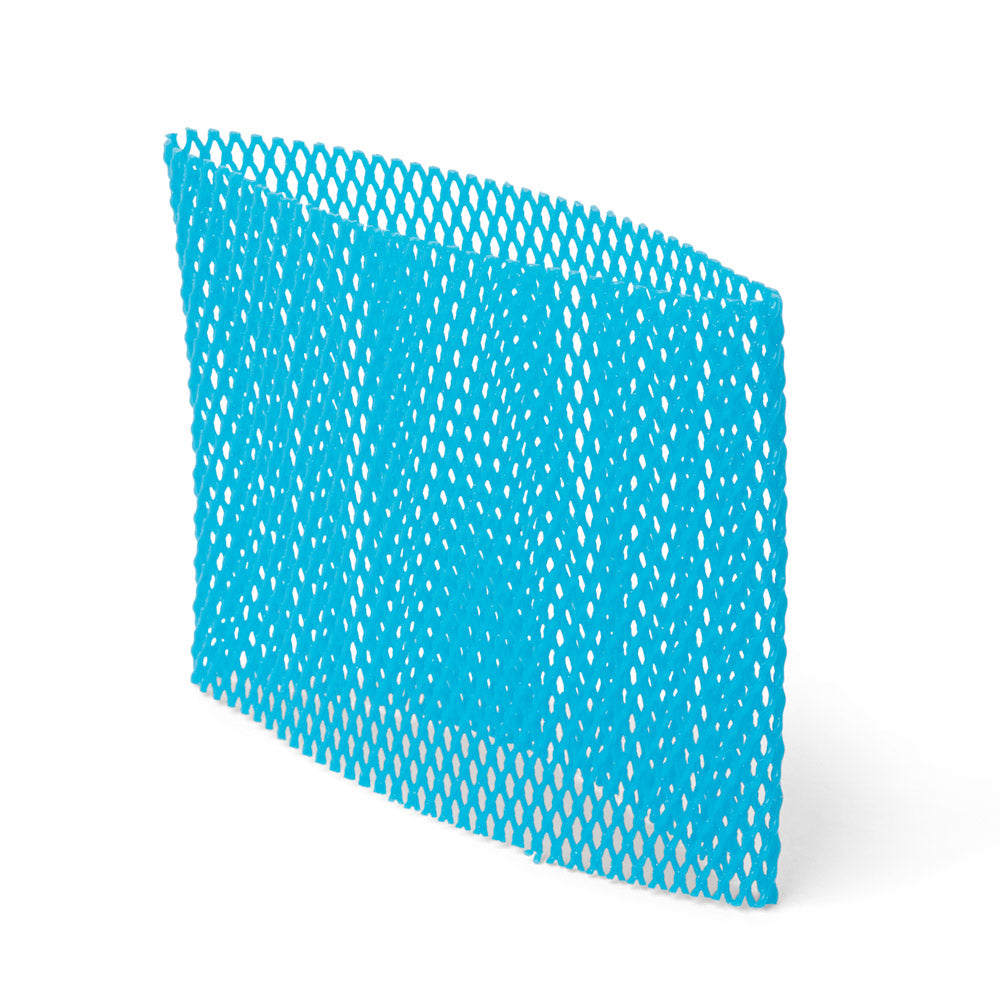

CorrNetting Protective tubular netting is a non-woven material crafted from the finest PE resin. It is infused with multimetal Vapor phase Corrosion Inhibitors (VpCI) through a cutting-edge extrusion process. It sets a new standard for top-tier packaging.

The protective tubular netting combines physical protection through cushioning and unmatched multimetal corrosion protection. It is invaluable for safeguarding delicate mechanical parts and sensitive materials. This packaging ensures that your mechanical and metal products reach their destination in pristine condition.

With CorrNetting, you can significantly reduce packaging waste, packing volume, shipping expenses, and potential damage caused by atmospheric corrosion. By incorporating advanced Cortec® multimetal Vapor phase Corrosion Inhibitors, it forms an invisible shield around the items from corrosion during transit and storage.

CorrNetting boasts exceptional toughness, durability, and reusability perfect for heavy-duty industrial applications. Some applications include heavy-duty industrial parts separation, surface protection, and precision metal parts packaging. In the automotive industry, you can use CorrNetting proves in tubular netting for spring silencers, protective covers for door assemblies, and wall support for filter systems.

The material's unique composition can withstand the harshest industrial environments while providing optimal cushioning for valuable mechanical parts and sensitive materials.

Features of Tubular Netting

Corr Netting offers many features for valuable items during transportation and storage:

- Versatile. Versatility is another feature of Corr Netting. The protective tubular netting is available in various mesh sizes and diameters, flat sheets, and tubular forms. This flexibility allows for tailored packaging solutions to suit specific requirements.Plus, you can further enhance the convenience of Corr Netting because you can opt to receive it in rolls or pre-cut pieces. This flexibility allows for easy usage in various packaging operations, ensuring seamless integration into existing systems.

- Durable. Durability is a top priority in packaging, and Corr Netting is built to last. This netting is tough and highly resilient. You can reuse it for multiple packaging cycles. Despite its robustness, Corr Netting is surprisingly lightweight, reducing overall package weight and shipping costs.Moreover, Corr Netting boasts excellent strength and conformability. It adapts to the contours of the products, providing a snug fit that reinforces the protective layer around each item.

- Dual Layer Protection. One of the standout qualities of Corr Netting is its ability to provide a dual-layered shield. Not only does it offer exceptional corrosion protection, but it also acts as a cushioning material, absorbing shocks and impacts during transit. This combination ensures that delicate or sensitive items remain undamaged and in good condition upon arrival.Corr Netting is its unparalleled multimetal corrosion protection. This unique feature safeguards packaged goods from rust and corrosion, even when in contact with different metals.Another crucial benefit of Corr Netting is its ability to facilitate airflow around the packaged items. This feature is vital in mitigating moisture buildup, preventing the development of mold or mildew that could harm the goods during prolonged storage.

- Affordable and Eco-Friendly. From a financial standpoint, Corr Netting offers a cost-effective packaging solution. Its durability and reusability significantly reduce the need for frequent replacements, saving both money and resources.Corr Netting stands out as an eco-friendly packaging solution. Its composition is recyclable and contributes to reducing environmental impact.This protective netting is an affordable choice for the packaging industry. The low-cost nature of this netting makes it an attractive option for businesses seeking reliable packaging solutions without breaking the bank.

Product Variety

CorrNetting, a protective tubular netting widely used in the packaging industry, offers a diverse range of options. It is available in various mesh sizes and diameters, offering flexibility to cater to different packaging needs. You can opt for either tubular form or flat sheeting, depending on your specific requirements. For detailed information on minimum order quantities and precise sizing, kindly reach out to Cortec.

Storage Recommendations

To ensure optimal performance and longevity, store CorrNetting indoors at room temperature. Make sure to keep the netting sealed within its original packaging to protect it from environmental factors. When stored under these favourable conditions, CorrNetting maintains its quality for up to twenty-four months.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is Cortec Cor-Netting, and how does it differ from regular protective netting?

Cortec Cor-Netting is a unique protective tubular netting that goes beyond simple physical cushioning; it's impregnated with Cortec's proprietary VpCI® (Vapor phase Corrosion Inhibitor) technology, meaning it actively protects metal parts from rust and corrosion while also providing physical protection. This dual action is what sets it apart from conventional netting.

• What is the core benefit of using Cor-Netting for packaging metal components?

The core benefit is getting both physical protection against bumps and scratches and powerful corrosion inhibition in one simple product. This means your delicate metal parts arrive at their destination or come out of storage rust-free and undamaged, without the need for additional messy rust preventative coatings.

• Is Cor-Netting suitable for protecting a wide variety of metals, or is it specific to certain types?

Cor-Netting is designed to offer multi-metal protection, which is fantastic for businesses that handle various types of metals. You don't need different packaging solutions for ferrous and non-ferrous metals; Cor-Netting has you covered across the board.

• How does the VpCI® technology within the netting actually prevent corrosion?

The VpCI® molecules integrated into the netting vaporize and form an invisible, protective molecular layer on the surface of your metal parts. This layer acts as a barrier, preventing oxygen, moisture, and other corrosive elements from reaching and reacting with the metal, effectively stopping rust in its tracks.

• Does the Cor-Netting leave any residue on the protected parts?

Absolutely not! One of the great advantages of Cortec's VpCI® technology is that it forms an invisible, molecular layer that doesn't leave any oily or greasy residue. Your parts are clean and ready for immediate use, which saves a lot of time and hassle.

Relevant products you may want to consider:

• Can Cor-Netting be reused or is it a single-use product?

Cor-Netting is designed to be reusable and is also 100% recyclable, making it an environmentally conscious choice for businesses looking to reduce waste and improve their sustainability efforts.

• Is Cor-Netting flexible enough to conform to irregularly shaped parts?

Yes, its tubular design and inherent flexibility allow it to adapt well to a variety of shapes and sizes, ensuring that even irregularly contoured components receive comprehensive physical and corrosion protection.

• What material is Cortec Cor-Netting made from?

Cortec Cor-Netting is typically extruded from high-quality polyethylene (PE) resin, which is then infused with the VpCI® formulation to provide both physical cushioning and corrosion inhibition.

• How long can I expect Cor-Netting to provide corrosion protection for my parts?

While specific durations can depend on the environment and how the netting is used, Cortec VpCI® products are generally known to provide effective corrosion protection for extended periods, often up to 24 months, especially when used within an enclosed package.

• Is Cor-Netting safe for workers to handle, and what about its environmental impact?

Cortec VpCI® products, including Cor-Netting, are formulated to be non-toxic and are free from harmful substances like chromates, heavy metals, nitrites, or chlorinated hydrocarbons, making them safe for personnel and environmentally friendly.

Relevant products you may want to consider:

• Where would Cor-Netting be most beneficial in a manufacturing process?

Cor-Netting truly shines in stages of manufacturing where metal components are moved between processes, stored temporarily, or prepared for shipping. It eliminates the need for repeated application and removal of traditional rust preventatives, streamlining the workflow and saving significant time.

• Can Cor-Netting be used for both short-term and long-term storage of metal parts?

Yes, Cor-Netting is versatile enough to provide effective corrosion protection for both short-term storage, such as work-in-process inventory, and for longer-term warehousing, ensuring parts remain pristine over extended periods.

• Is Cor-Netting suitable for protecting components during shipping, especially for international transit?

Absolutely! Cor-Netting is an excellent choice for protecting parts during transit, even for long-distance and international shipments where varying environmental conditions and potential moisture exposure could lead to corrosion. Its VpCI® technology creates a protective atmosphere within the packaging.

• What types of parts commonly benefit from Cor-Netting protection?

Sensitive mechanical parts, precision-machined components, gears, metal joints, and any delicate items that require both cushioning and corrosion protection are ideal candidates for Cor-Netting.

• Could Cor-Netting replace traditional oils or desiccants in certain packaging applications?

In many cases, yes. Cor-Netting offers a clean and dry alternative to traditional rust preventative oils, eliminating the messy application and removal steps. While desiccants address moisture, Cor-Netting’s VpCI® technology directly prevents the electrochemical reaction of corrosion, offering a more active form of protection.

Relevant products you may want to consider:

• How does Cor-Netting contribute to overall packaging efficiency?

By combining physical protection and corrosion inhibition into one product, Cor-Netting simplifies the packaging process. It eliminates the need for multiple layers of packaging materials and the labor-intensive steps associated with traditional rust prevention, thereby boosting efficiency.

• Can Cor-Netting be used inside existing shipping containers or crates?

Yes, it's designed to be easily incorporated into existing packaging schemes. You can simply apply the Cor-Netting directly to the individual parts, and then place them into your standard shipping containers or crates.

• Is it necessary to clean or degrease parts before applying Cor-Netting?

While it's generally good practice to ensure parts are clean and free of gross contaminants for optimal performance of any VpCI® product, Cor-Netting's VpCI® technology is quite effective and in many cases, parts are ready for immediate use without prior cleaning or degreasing when removed from Cor-Netting.

• Does Cor-Netting affect the appearance or performance of the metal parts it protects?

No, the invisible molecular layer formed by the VpCI® technology does not alter the appearance, conductivity, or any other critical properties of the metal parts, meaning they are ready for immediate use or further processing.

• Can Cor-Netting be used in conjunction with other Cortec VpCI® products for enhanced protection?

Absolutely. For complex or extremely sensitive applications, Cor-Netting can be part of a multi-pronged approach, combined with other Cortec VpCI® films, papers, or emitters to create a highly effective corrosion protection system.

Relevant products you may want to consider:

• How do I properly apply Cortec Cor-Netting to a component?

Applying Cor-Netting is straightforward; you simply slide the tubular netting over the component you wish to protect. Its elastic nature allows it to conform snugly to the part, providing both cushioning and an active corrosion-inhibiting environment.

• Are there different sizes or diameters of Cor-Netting available for various part sizes?

Yes, Cor-Netting typically comes in a range of diameters to accommodate different sizes of components, ensuring a snug and effective fit for optimal protection.

• What's the best way to store unused Cor-Netting to maintain its effectiveness?

To preserve its VpCI® properties, it's best to store unused Cor-Netting in its original packaging, sealed, and in a dry, temperate environment away from direct sunlight and extreme temperatures.

• Does the tension of the netting affect its protective capabilities?

While a snug fit is ideal for physical protection and for keeping the VpCI® environment contained, the VpCI® vapors will still migrate to all surfaces of the enclosed part regardless of slight variations in tension. However, ensuring good contact and coverage is always recommended.

• Is there a specific orientation or direction for applying the netting?

No, the tubular nature of Cor-Netting means there isn't a specific orientation. You just need to ensure the part is fully enclosed within the netting for the VpCI® to work its magic.

Relevant products you may want to consider:

• How can I ensure the VpCI® protective atmosphere is maximized when using Cor-Netting?

For maximum effectiveness, ensure that the part is fully encased by the netting and, if possible, consider placing the netted part within a sealed or enclosed package. This helps to concentrate the VpCI® vapors and maintain the protective atmosphere.

• What should I do if the Cor-Netting gets torn or damaged before use?

If the Cor-Netting is significantly torn, its physical cushioning properties might be compromised, and the VpCI® effectiveness could be reduced as the vapors might escape. It's best to use undamaged netting for optimal protection.

• Does humidity or temperature affect the performance of Cor-Netting?

Cortec VpCI® technology is designed to perform effectively across a wide range of temperatures and humidity levels. The VpCI® molecules are volatile enough to vaporize and protect in various environmental conditions.

• How do I dispose of Cor-Netting after use?

As Cor-Netting is 100% recyclable polyethylene, it can typically be disposed of through standard plastic recycling channels, which is a great benefit for sustainable waste management.

• Are there any industry standards or certifications that Cor-Netting complies with?

While the product page doesn't explicitly list specific certifications for Cor-Netting itself, Cortec VpCI® technology is widely recognized and often meets various industry and military specifications for corrosion prevention. It's always a good idea to check specific product data sheets for any particular compliance needs.