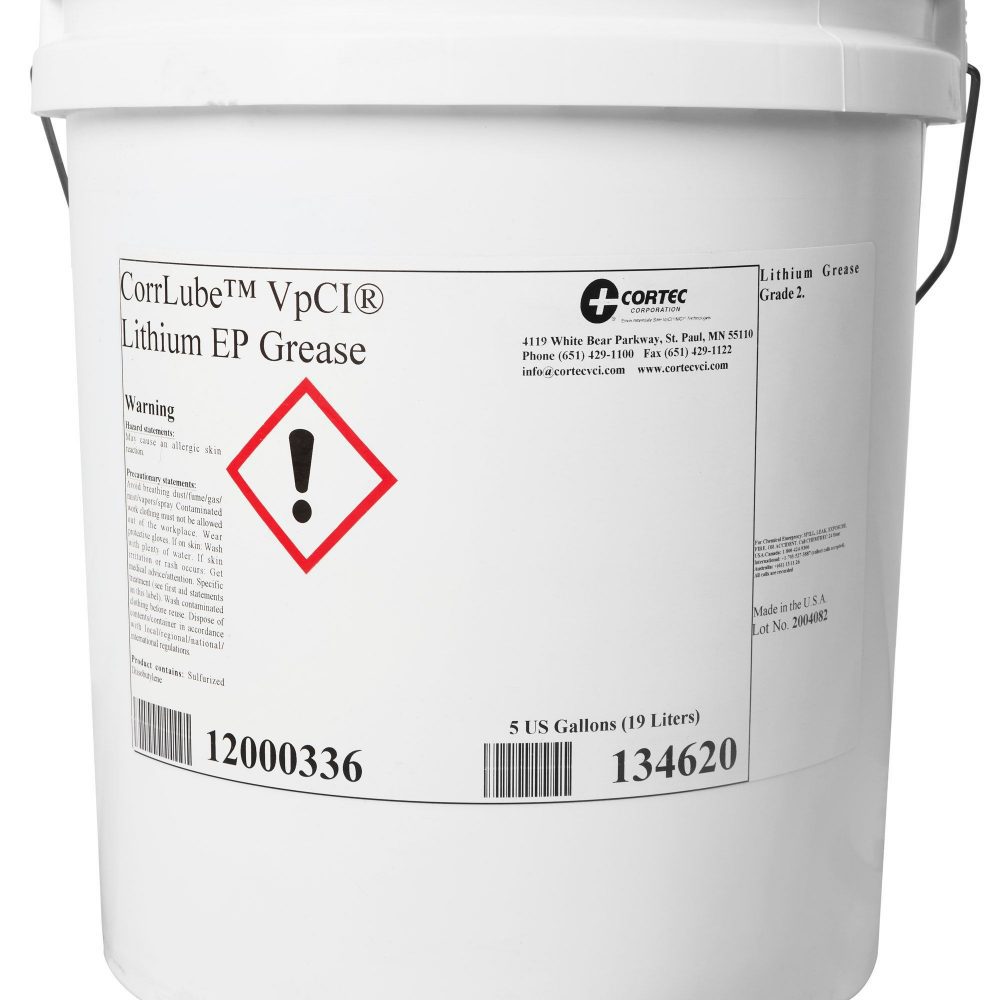

Cotrec CorrLube™ VpCI Lithium EP Grease 5 Gallon Drum Pails & 14.5 Ounce Cartridges

Cotrec CorrLube™ VpCI Lithium EP Grease 5 Gallon Drum Pails & 14.5 Ounce Cartridges

Couldn't load pickup availability

Corrlube VpCI Lithium EP Grease is a best in class ‘extreme pressure’ VpCI grease ideal for use with machine parts and components.

Available in both 14.5 ounce cartridges & 5 gallon (19 Ltr) drum pails.

CorrLube™ VpCI® Lithium EP Grease is a cutting-edge lithium complex grease. It provides unparalleled resistance to oxidation, ensuring exceptional performance under various conditions. This advanced formulation boasts remarkable stability even at high temperatures, making it an ideal choice for demanding industrial applications.

Whether during active operations or periods of equipment storage, CorrLube™ VpCI® Lithium EP Grease delivers unwavering reliability. Its versatility allows its effective use during layup conditions and regular operation, saving you the hassle of switching greases based on usage scenarios.

This VpCI Grease has corrosion-inhibiting properties, protecting metal parts from saltwater, brine, H2S, HCl, and other aggressive corrosive agents. It ensures your equipment remains protected even in harsh and corrosive environments.

Packaging & Storage of Corrlube VpCI Lithium EP Grease

CorrLube™ VpCI® Lithium EP Grease is a premium lubricant that provides exceptional protection against corrosion and wear in various applications. This high-performance grease is available in two convenient packaging options: 14.5-ounce cartridges, 12 cartridges neatly packed in each carton, and 5-gallon (19-liter) pails.

It is essential to follow proper storage guidelines. Store CorrLube™ VpCI® Lithium EP Grease in its original packaging indoors. To further maintain its quality, keep the product away from direct sunlight. The recommended storage temperature range is between 40 and 100 °F (4-38 °C). Shelf life is 2 years.

Advantages of VpCI Grease

CorrLube™ VpCI® Lithium EP Grease offers a host of advantages that make it a superior choice for various applications.

- Cleaner application, which reduces the dripping and spattering of the lubricant.

- Advanced grease formulation which provides exceptional lubrication for extended periods.

- Reduced need for frequent reapplication.

- Improvement in the effectiveness of seals, helping to keep contaminants at bay.

- Maintains its lubricating properties even during periods of equipment rest.

- Prevents issues on dry starts.

- Reduces overall friction and wear.

- Aid in the suspension of solids, further enhancing their lubrication capabilities.

- Excellent performance under high temperatures, high pressures, low speeds with high pressures, or shock loading.

Typical Applications

Some of the typical applications where CorrLube™ VpCI® Lithium EP Grease excels include:

- Lubricating Sleeves. CorrLube™ VpCI® Lithium EP Grease ensures smooth and efficient operation of sleeves, preventing wear and enhancing their overall lifespan.

- Ball and Roller Bearings. This specialised grease provides exceptional lubrication to the ball and roller bearings. It reduces friction and protects against corrosion. As a result, it extends bearing life and enhances performance.

- Vehicle / Equipment Chassis. CorrLube™ VpCI® Lithium EP Grease is an excellent choice for lubricating chassis components, ensuring their smooth movement and safeguarding them against corrosion caused by exposure to environmental elements.

- Fan Bearings.When applied to fan bearings, this grease not only reduces noise but also protects against rust and wear, maintaining optimal fan performance and reliability.

- Bushings. CorrLube™ VpCI® Lithium EP Grease effectively lubricates bushings, reducing friction and preventing surface damage, which is crucial for their efficient operation.

- Pulley Bearing. Pulley bearings can benefit from the superior lubrication and anti-corrosion properties of CorrLube™ VpCI® Lithium EP Grease, ensuring smooth rotation and preventing downtime due to wear-related failures.

- Sliding High-Friction Areas. In applications with high-friction areas, such as sliding mechanisms, CorrLube™ VpCI® Lithium EP Grease minimises friction and wear, thereby extending the service life of critical components.

- Generator End Bearings. The high-performance characteristics of this grease make it an excellent choice for lubricating generator end bearings, offering protection against rust and wear during the generator’s operation.

Overall, CorrLube™ VpCI® Lithium EP Grease proves to be an indispensable asset in numerous industrial settings. It improves the efficiency, reliability, and longevity of diverse equipment and machinery. Its ability to combine lubrication with advanced corrosion protection makes it a reliable choice for demanding applications, especially if uptime is important.

Method of Application

You can use a brush, grease gun, or automatic applicator. Avoid using with bare hands and make sure to wear protective gear when using. Although the grease is resistant to high or low temperatures, take note of the temperature range for it to be effective. The temperature range should be between -22 and 266 °F or -30 to 130 °C.

Product Specifications (.PDF)

Frequently Asked Questions

• So, what exactly is CorrLube VpCI Lithium EP Grease?

It's a top-tier lithium complex grease, specifically designed to offer superior lubrication and, critically, exceptional corrosion protection. Think of it as a hardworking lubricant with a built-in rust-fighting shield for your machinery.

• What makes it different from a regular grease I might use?

Unlike standard greases, CorrLube VpCI Lithium EP Grease incorporates advanced Vapor phase Corrosion Inhibitors (VpCI®). This means it not only protects surfaces it directly touches, but also releases a protective vapor that reaches hard-to-access areas within enclosed spaces, offering a more comprehensive shield against rust.

• What's the "EP" in its name stand for?

The "EP" stands for "Extreme Pressure." This indicates that the grease is formulated to perform exceptionally well under high-pressure conditions, heavy loads, and even shock loading, preventing metal-to-metal contact and wear.

• Is it suitable for use in tough environments?

Absolutely. This grease is engineered to thrive in extreme operating conditions, providing reliable protection against highly corrosive agents like saltwater, brine, hydrogen sulfide (H₂S), and hydrochloric acid (HCl).

• What's its primary role – just lubrication, or something more?

Its primary role is a powerful combination of both lubrication and advanced corrosion inhibition. It ensures smooth operation of components while actively preventing rust and degradation, extending the lifespan of your equipment.

Relevant products you may want to consider:

• How do I actually apply CorrLube VpCI Lithium EP Grease to my equipment?

You can apply it using common methods like a brush, a standard grease gun, or even an automatic applicator for larger or more complex systems. It’s designed for straightforward application.

• Can I use it for equipment that sits idle for a while, like during a shutdown?

Yes, that's one of its standout features! CorrLube VpCI Lithium EP Grease is uniquely suitable for both operating and layup conditions. You don't need to switch greases when transitioning from active use to storage, which is a huge time-saver and simplifies maintenance.

• What's the ideal temperature range for this grease to perform effectively?

This grease is quite versatile, operating effectively within a broad temperature range from -22°F to 266°F (-30°C to 130°C). This wide range makes it suitable for many different climates and operational demands.

• Do I need to remove old grease before applying CorrLube VpCI Lithium EP Grease?

While general good maintenance practice often recommends cleaning old grease, a significant advantage of this product for layup situations is that it eliminates the need to remove special preservation grease and then re-apply operational grease. It works well for intermittent operation without requiring those extra steps.

• How does it help seals perform better?

CorrLube VpCI Lithium EP Grease helps to make seals more effective at keeping contaminants out, contributing to a cleaner operating environment for your machinery's internal components.

Relevant products you may want to consider:

• Where can I typically use CorrLube VpCI Lithium EP Grease in my machinery?

It's incredibly versatile, commonly used for lubricating sleeves, ball and roller bearings, vehicle and equipment chassis components, fan bearings, bushings, pulley bearings, sliding high-friction areas, and even generator end bearings.

• Is it suitable for heavy-duty industrial machinery?

Absolutely, it's an excellent choice for demanding industrial applications, especially where high temperatures, high pressures, low speeds with high pressures, or shock loading are present.

• Can it protect my equipment if it's exposed to harsh outdoor or marine conditions?

Yes, this grease is specifically formulated with superior corrosion-inhibiting properties against saltwater, brine, H₂S, and HCl, making it ideal for equipment in coastal environments, offshore platforms, or any area with high humidity and airborne corrosives.

• My equipment often experiences "dry starts." Will this grease help?

Yes, it actively helps prevent issues associated with dry starts, which is crucial for reducing wear and tear on components, especially after periods of inactivity.

• Is it good for components that experience a lot of friction?

Definitely. In applications with high-friction areas, like sliding mechanisms, CorrLube VpCI Lithium EP Grease is designed to minimize friction and wear, significantly extending the service life of those critical components.

Relevant products you may want to consider:

• How does this grease offer "longer lubrication periods"?

Its advanced formulation provides exceptional lubrication for extended periods, meaning you won't need to reapply it as frequently as some other greases, which saves time and maintenance costs.

• What kind of corrosion protection does it provide beyond just being a barrier?

Beyond forming a physical barrier, it utilizes Vapor phase Corrosion Inhibitor (VpCI®) technology. These VpCI molecules evaporate and form a protective layer on metal surfaces, even in areas not directly coated by the grease, providing comprehensive multi-metal protection.

• Does it maintain its lubricating properties even when machinery isn't running?

Yes, it's formulated to maintain its lubricating properties even during periods of equipment rest, ensuring that components remain protected and ready for operation.

• Can it help reduce overall friction and wear in my equipment?

Indeed, its high-performance formulation is designed to significantly reduce overall friction and wear on metal components, leading to smoother operation and a longer service life for your machinery.

• What is its dropping point, and why is that important?

Its dropping point is 360°F (182°C). The dropping point is the temperature at which a grease changes from a semi-solid to a liquid state, indicating its high-temperature stability and suitability for demanding applications.

Relevant products you may want to consider:

• What is the NLGI Grade of CorrLube VpCI Lithium EP Grease?

It is an NLGI Grade 2 grease, which is a common and versatile consistency suitable for a wide range of general-purpose applications.

• What does "lithium complex grease" mean in terms of its composition?

A lithium complex grease is formulated with a special soap thickener system that provides excellent resistance to oxidation, high-temperature stability, and good water resistance, making it a very robust choice.

• Is this grease resistant to oxidation?

Yes, it offers excellent resistance to oxidation, which means it resists breaking down or degrading when exposed to air and heat, contributing to its long service life and stable performance.

• What color is the grease?

The grease typically has a dark gray color.

• Does it have any specific certifications or meet particular standards?

While the provided information doesn't list all certifications, its superior corrosion inhibition against agents like H₂S suggests it's designed to meet rigorous industrial demands.

Relevant products you may want to consider:

• How is CorrLube VpCI Lithium EP Grease typically packaged?

It's conveniently available in 14.5-ounce cartridges, usually packed 12 cartridges per carton, and also in larger 5-gallon (19-liter) pails.

• What are the recommended storage conditions for this grease?

To ensure its best performance and shelf life, it's recommended to store the grease in its original packaging indoors, away from direct sunlight, and within a temperature range of 40°F to 100°F (4°C to 38°C).

• What's the shelf life of CorrLube VpCI Lithium EP Grease?

It has a shelf life of 2 years when stored properly according to the recommended guidelines.

• How can using this grease potentially save me money?

By providing longer lubrication periods, reducing the need for frequent reapplication, preventing dry starts, and offering superior corrosion protection, it extends equipment lifespan and reduces maintenance costs, ultimately leading to significant savings.

• Is there anything else I should know about handling this product safely?

While it's designed for effective use, it's always wise to avoid direct skin contact and wear appropriate protective gear when applying it, as with any industrial lubricant.

• Does this grease help in suspending solid additives if I were to use them?

Yes, it effectively aids in the suspension of solid additives such as graphite or molybdenum disulfide, further enhancing its lubrication capabilities.