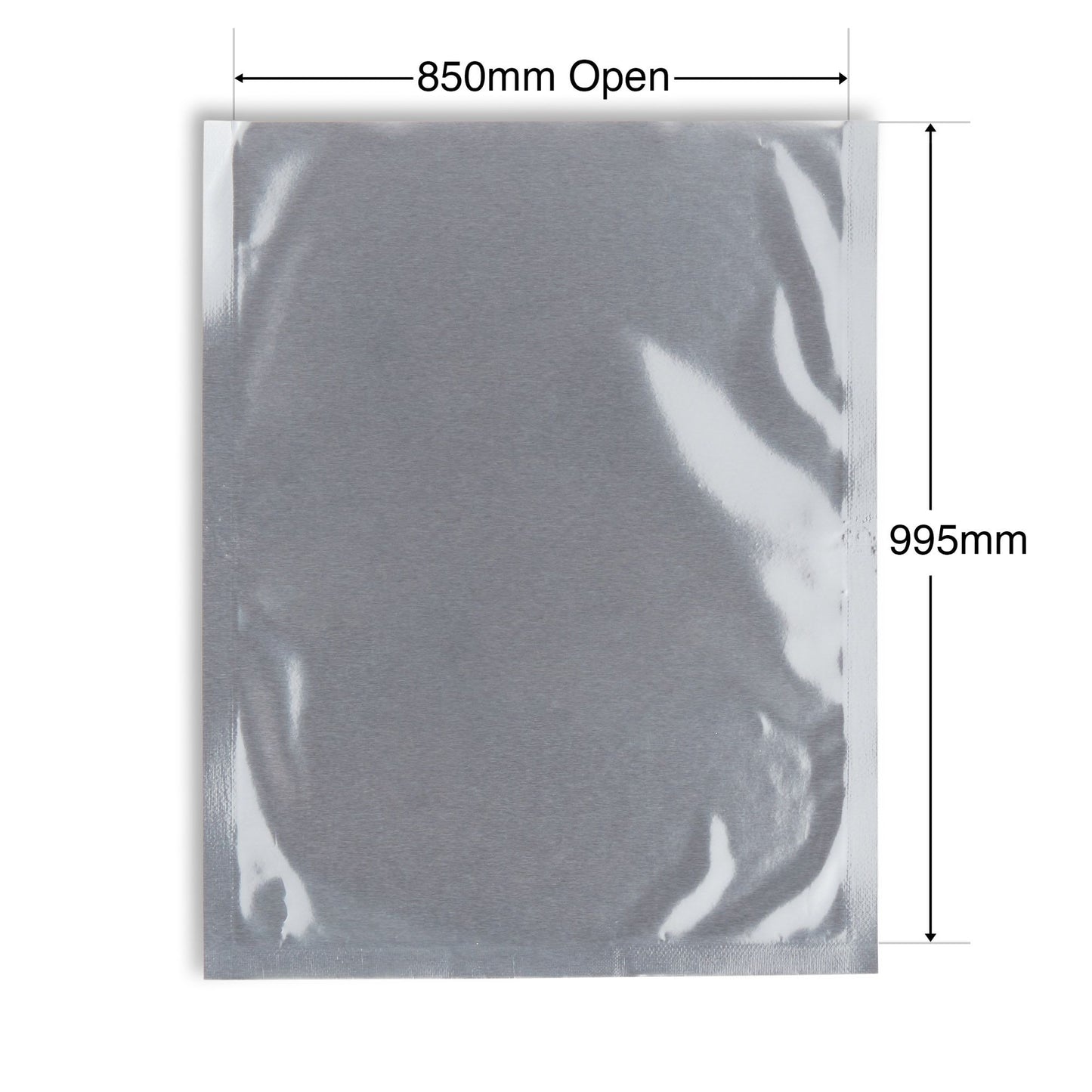

Heat Seal Foil Bags, Foil Pouches, VAL55HD™ Stock Pre Cut & Manufactured To Order

Heat Seal Foil Bags, Foil Pouches, VAL55HD™ Stock Pre Cut & Manufactured To Order

156 in stock

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Our Barrier Foil Bags feature either 8mm or 12mm seals. We supply from as few as 50 pieces.

This material is an exclusive high performance aluminium barrier laminate foil. It is our most popular construction for good reason.

It displays both high strength and high barrier properties. When compared to competitors laminates the VAL55HD demonstrates a build that is lighter but stronger.

Perfect for protecting sensitive items from moisture and corrosion damage. Anywhere this may occur during transport and storage in the supply chain.

Made to order sizes can include tear notches fitted for easy opening.

- Conforms with DEF STAN 81-147 (formerly DEF STAN 81-75)

VAL55HD™ Heat Seal Foil Bags Packaging

These aluminium foil bags are laminated with Polyester and Polythene layers, producing the ‘barrier’. Designed to protect your goods when being transported and stored.

This construction gives optimal protection for goods. Particularly those that are vulnerable to moisture and corrosion damage. Shippers can also encounter many other hazards in the supply chain. Like salt water, gas products and marine air.

Manufactured from our VAL55HD™ laminated film. This construction is widely considered a ‘best in class’ moisture barrier packaging.

An ultra low water vapour transmission rate to ensure that once closed with a heat sealer. The bag will continue to protect your valuable goods into the long term.

Foil Pouches For Long Term Asset Preservation & Storage Packaging

Clients for this product operate in a wide variety of markets.

They perform well when protecting moisture sensitive products. Like powdered granules and consumables. To manufactured and precision engineering parts.

Packaging materials of this kind are excellent for shipments that may have lengthy transport times. As well they may go into storage at the end of this.

Ideal to ensure that the product reaches the end user in factory condition.

Clients can buy these Barrier foil bags supplied in standard sizes for convenience. With ‘easy open’ tear notches included.

Heat Seal Bag Compatibility

Primarily Industrial Packaging. Sea shipping and Long term storage projects. Industries include Aerospace, Automotive, Medical Equipment and Electronics.

It’s perfect as pouch packaging for sensitive items. Meeting the Def Stan 81-147 (formerly Def Stan 81-75) specifications. (For MIL-PRF-131-K Class 1 foils consider our VAL59HS™ or VAL131HD Specs)

Just let us know if you have any specific requirement at the order stage.

If you require the VAL55HD on a roll take a look at our reel stocks.

Benefits of VAL55HD™ Barrier Foil Bags Vs Foil Lined Paper

- Very high tear resistance.

- Three side seal design.

- Ideal for products with sharp edges.

- Market leading performance.

- Lower packaging costs overall.

- Low carbon product.

- Sizes can be adapted with tear nicks for easy opening.

- Handling.

Requires heat sealing with a compound foil bag sealer. Set to 180°c for 2 seconds.

Please note – this product is intended for use by appropriately trained professionals. Use in conjunction with Silica Gel Sachets for optimal performance.

Technical Data

12 PET / 12 PE / 7 ALU / 20 PE / 60 HDPE.

Above is our standard VAL55HD commercial construction however our range is vast and included specification such as pet/alu/pe , pet/alu/lldpe & MET Pet Film & Foil Packaging.

Delivery time for Barrier Foil Bags

Pre cut stock sizes are available ex stock for online ordering.

Manufactured to order, bespoke sizes and formats are dependant on quantity and specification but most requirements can be fulfilled within 4 weeks.

Custom foil pouch production is usually 7 – 10 Workings Days.

Modification and additional fittings such as valves, heat seal zip lock ports & carry handles will require additional manufacturing time.

Please note – these products are cut to order in production runs. Often we will have these in stock in which case delivery can be expected in 3 – 4 days. However in the event of low stock please allow 7 – 10 days for production and delivery.

For more information on our foil pouches & heat seal foil bags contact us.

Product Specifications (.PDF)

Frequently Asked Questions

• What are VAL55 Heat Seal Foil Bags, and what makes them a top choice for protection?

VAL55 Heat Seal Foil Bags are high-performance aluminium barrier laminate foil bags from Valdamark Direct, specifically engineered to provide superior protection for sensitive items. Their unique multi-layer construction, featuring Polyester, Aluminium, and Polythene, creates an exceptional barrier against moisture, corrosion, oxygen, and other environmental hazards, making them a "best in class" solution for critical packaging needs.

• How do VAL55 bags create such an effective protective barrier?

The effectiveness of VAL55 bags stems from their sophisticated five-layer laminate construction. This design strategically combines complementary materials like PET, PE, Aluminium, and HDPE, forming a robust barrier that effectively seals out moisture, oxygen, UV light, and even aggressive gases, providing a highly stable internal environment for your products.

• Are VAL55 Heat Seal Foil Bags environmentally friendly or recyclable?

While the multi-material laminate provides exceptional barrier properties, the composition of aluminium foil laminated with various plastics can make single-stream recycling challenging in some areas. However, aluminium itself is widely recycled, and the robust protection offered by VAL55 bags can significantly extend the shelf life of products, potentially reducing waste from spoilage.

• What types of products are best suited for packaging in VAL55 Heat Seal Foil Bags?

VAL55 bags are ideal for a vast array of moisture-sensitive and corrosion-prone products. This includes everything from precision engineering parts and manufactured components to sensitive electronics, powdered granules, and even certain consumables that require long-term preservation during transport and storage.

• What is the core benefit of using VAL55 bags over other packaging materials like foil-lined paper?

Compared to foil-lined paper, VAL55 bags offer significantly higher tear and puncture resistance, superior barrier performance, and excellent seal strength. Their market-leading construction ensures far better long-term protection, making them more reliable for safeguarding high-value or delicate items.

Relevant products you may want to consider:

• Can VAL55 Heat Seal Foil Bags be used for international shipping, especially sea freight?

Absolutely! VAL55 bags are specifically designed for demanding transport conditions, including lengthy international shipments and sea freight, where products are often exposed to high humidity, salt water, and marine air. They ensure your goods arrive at their destination in factory condition.

• Are VAL55 bags suitable for long-term storage of valuable assets?

Yes, these bags are an excellent choice for long-term asset preservation and storage. When properly heat-sealed, their ultra-low water vapor transmission rate maintains a stable, protective environment inside, crucial for preventing degradation of sensitive items over extended periods.

• Can I use VAL55 bags to protect sensitive electronic components from moisture damage?

Definitely. The superior moisture and oxygen barrier properties of VAL55 bags make them highly effective for protecting sensitive electronic components from humidity, which can lead to corrosion and malfunction.

• Are these bags appropriate for medical equipment or pharmaceutical packaging?

Yes, Valdamark's high-performance foil packaging, including the VAL55 material, is manufactured to conform to high standards and is widely used in regulated sectors like medical, healthcare, and pharmaceutical packaging due to its protective properties and ability to maintain product integrity.

• Do VAL55 Heat Seal Foil Bags offer protection against odors and gases?

Yes, the aluminium layer within the VAL55 laminate acts as a strong barrier against aggressive gases and prevents odor transfer, which is vital for preserving the integrity and quality of certain products.

Relevant products you may want to consider:

• Can VAL55 bags be used for products with sharp edges without risk of puncture?

The VAL55 material boasts very high tear and puncture resistance due to its robust construction. This makes it an ideal choice for packaging items that might have sharp edges, minimizing the risk of damage to the bag and its contents.

• What kind of equipment do I need to seal VAL55 Heat Seal Foil Bags effectively?

To achieve a secure, hermetic seal with VAL55 bags, you will need a compound foil bag sealer. These heat sealers are specifically designed to work with multi-layer foil laminates.

• What are the recommended temperature and time settings for heat-sealing VAL55 bags?

For optimal sealing, it is recommended to set your compound foil bag sealer to approximately 180°C (356°F) and apply heat for about 2 seconds. Always consult your sealer's instructions and test on a scrap piece first to ensure a good seal.

• Is it necessary to use desiccant sachets in conjunction with VAL55 bags?

While VAL55 bags offer exceptional moisture barrier properties, for optimal performance, especially with highly moisture-sensitive products or for long-term storage, it is strongly advised to use them in conjunction with desiccant sachets. This helps to absorb any residual moisture within the sealed environment.

• Can VAL55 bags be used for vacuum packaging?

Yes, the VAL55 material can be used for vacuum packaging, ensuring a tightly sealed environment that further minimizes the presence of oxygen and other atmospheric contaminants around your product.

Relevant products you may want to consider:

• Are there any specific handling precautions when working with VAL55 material?

Valdamark Direct advises that this material should be handled and used by appropriately trained professionals, especially when operating heat-sealing equipment, to ensure safety and proper application.

• How do I ensure a perfect seal when using VAL55 bags?

Beyond the correct temperature and dwell time, ensure the sealing area is clean and free of any dust, debris, or product particles. A clean sealing path is crucial for an airtight and durable seal.

• What is the typical construction of the VAL55HD™ laminated film?

The standard VAL55HD™ commercial construction is a sophisticated five-layer laminate consisting of 12µm PET, 12µm PE, 7µm Aluminium, 20µm PE, and 60µm HDPE, providing its market-leading barrier properties.

• What kind of water vapor transmission rate (WVTR) can I expect from a sealed VAL55 bag?

Once properly heat-sealed, VAL55 bags achieve an ultra-low water vapor transmission rate (WVTR), creating an optimal environment for sensitive items and ensuring long-term protection against moisture ingress.

• Does VAL55 material conform to any military specifications?

Yes, the VAL55HD™ material is manufactured to conform in full to the UK Ministry of Defence standard DEF STAN 81-147 (formerly DEF STAN 81-75). For US military specification MIL-PRF-131K Class 1, Valdamark offers other specific materials like VAL59HS™ or VAL131HD.

Relevant products you may want to consider:

• What is the typical bond strength between the laminated layers of VAL55?

The VAL55 material displays excellent bond strength between each of its laminated layers, which contributes significantly to its overall durability, robustness, and barrier integrity.

• Can VAL55 bags withstand a wide range of temperatures during transport and storage?

Yes, this alu foil packaging is designed to maintain its performance within a wide operating temperature range, typically from -40°C to +70°C, making it suitable for diverse environmental conditions during transit and storage.

• How does the aluminium layer specifically contribute to the barrier properties of VAL55 bags?

The aluminium layer is absolutely critical; it provides an almost impermeable barrier against moisture vapor, oxygen, and UV light. It essentially acts as a "flexible tin can," sealing your products from external environmental elements.

• Are VAL55 Heat Seal Foil Bags available in custom sizes or only standard pre-cut dimensions?

While standard pre-cut sizes are available for immediate online ordering, Valdamark Direct specializes in bespoke solutions. They can manufacture custom sizes and formats, including those with tear notches for easy opening, depending on your specific requirements and quantity.

• What is the typical lead time for custom-ordered VAL55 foil pouches?

Custom foil pouch production usually has a lead time of 7-10 working days. If modifications or additional fittings like valves, zip-lock ports, or carry handles are needed, additional manufacturing time will be required.

Relevant products you may want to consider:

• Can I purchase VAL55 material on a roll if I prefer to cut and form my own bags?

Yes, if you require the VAL55HD™ material on a roll, Valdamark Direct offers it in various widths, mainly as 200-meter linear log rolls, allowing you to convert the material to your desired dimensions.

• Is there a minimum order quantity for VAL55 Heat Seal Foil Bags?

Valdamark Direct offers flexibility, with quantities available from as few as 50 pieces for stock sizes, making them accessible for both small and large-scale projects.

• Does the VAL55 material offer any protection against static discharge for electronics?

While the primary function of VAL55 is as a moisture and oxygen barrier, some foil laminates also provide a degree of static shielding due to the conductive nature of the aluminium layer. For critical ESD protection, specific static shielding bags designed to create a Faraday cage are typically recommended.

• How does using VAL55 bags contribute to overall lower packaging costs?

By providing superior long-term protection, VAL55 bags help prevent product damage and spoilage, which can significantly reduce costly returns, rework, and waste. This long-term product integrity often leads to lower overall packaging costs.

• What is the shelf life of products packaged within a sealed VAL55 Heat Seal Foil Bag?

When properly heat-sealed and combined with appropriate desiccants, VAL55 bags can significantly extend the shelf life of dry goods, often for many years, by maintaining an extremely low internal moisture and oxygen level. The exact shelf life will depend on the specific product and storage conditions.