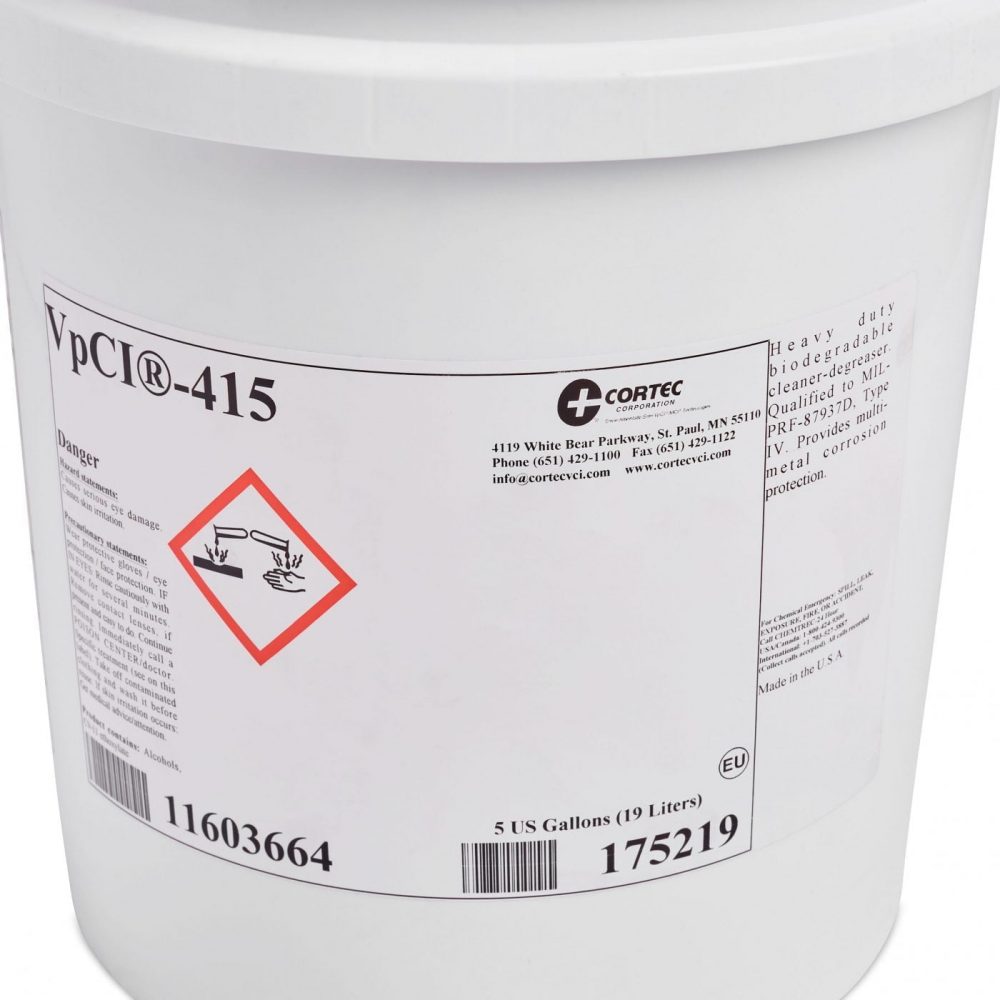

Cortec VpCI® 415 Corrosion Inhibitor Formula Heavy-Duty Biodegradable Water-Based Alkaline Cleaner and Degreaser

Cortec VpCI® 415 Corrosion Inhibitor Formula Heavy-Duty Biodegradable Water-Based Alkaline Cleaner and Degreaser

Low stock: 6 left

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

Cortec VpCI®415 is a heavy-duty biodegradable water-based alkaline cleaner and degreaser offering unique flash corrosion protection.

VpCI®-415 can provide corrosion protection for up to 6 months during indoor storage. VpCI®-415 is formulated to meet the requirements for cleaning and corrosion protection of aircraft. The compounds contained in VpCI®-415 function by altering hydrocarbons so that the deposits can be removed with water. VpCI®-415 can be metered into power washers, steam cleaners, dip tanks and other cleaning equipment. Along with good detergent properties, VpCI®-415 is hard water stable.

VpCI 415 from Cortec is a MIL-PRF-87937D Type IV approved biodegradable heavy duty cleaner degreaser. As well VpCI 415 can provide continual corrosion protection for a range of metals that are to be stored indoors.

VpCI 415 is an excellent choice for those who require a heavy-duty industrial degreaser that conforms to MIL SPEC requirements but is also multi-purpose and an environmentally conscious product.

Using Cotec’s sophisticated vapour phase corrosion inhibitors, the VpCI Preservation method offers metal surfaces complete and optimal protection.

VpCI 415 formula features

- Outstanding pitting corrosion resistance

- Impressive cleaning action even at low temperatures

- Displays a tolerance for hard water

- Stable when moving through freeze and thaw cycles

- Compatible with pressure washers & hoses as well as steam cleaners, industrial mops, foam applicators and dipping trays

Environmental Credentials

- Biodegradable (using the shake flask experiment biodegradation test method)

- Non-toxic as per EPA 600/4-90/027

- Non-corrosive as per MIL-PRF-87937D

- Does not inhibit pollution abatement systems

- Hazardous Air Pollutants (HAPS) free

- Ozone depleting substances (ODS) free

- Non-flammable & non combustible

- Caricigen & Ketone free

- Nonlphenolethoxylates

- TO 1-1-691

- TO 36-1-191

- TO 1-1-689-3

- TO 1-1-689-5

- TO 35-1-3

- TM 1-1500-344-23

- TO-23’s or equivalent

- Conforms to Boeing D6-17487 Rev P

Packaging Format

VpCI®-415 is readily available in either 5 gallon (19ltr) or 55 gallon (208 ltr) bulk drums. VpCI 414 has a 24 month shelf life.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is Cortec VpCI-415 and what makes it special?

Cortec VpCI-415 is a robust, biodegradable, water-based alkaline cleaner and degreaser that does more than just clean; it also offers unique flash corrosion protection. What truly sets it apart is its ability to tackle heavy-duty cleaning tasks while simultaneously providing temporary multi-metal corrosion inhibition for up to six months during indoor storage, meaning you're not just cleaning, you're protecting in one simple step.

• How does Cortec VpCI-415 actually work to clean and protect metals?

This intelligent solution works by altering hydrocarbon deposits, such as oils and greases, allowing them to be easily removed with water. Beyond just cleaning, its advanced Vapor phase Corrosion Inhibitor (VpCI) technology forms a protective molecular layer on metal surfaces, effectively preventing flash rust and guarding against further corrosion.

• Is Cortec VpCI-415 environmentally friendly?

Absolutely! Cortec VpCI-415 is designed with environmental responsibility in mind. It's biodegradable, non-toxic, non-corrosive, and importantly, it's free from VOCs (Volatile Organic Compounds), hazardous air pollutants (HAPS), ozone depleting substances (ODS), and nonylphenolethoxylates. This makes it a much safer choice for both the environment and the folks using it.

• What types of materials can I safely use Cortec VpCI-415 on?

Cortec VpCI-415 is a versatile solution suitable for a wide range of metals, including steel, cast iron, galvanized steel, stainless steel, aluminum, copper, and brass. Its multi-metal protection capabilities ensure it's a go-to for diverse industrial applications.

• How long does the corrosion protection from Cortec VpCI-415 typically last?

When used for indoor storage, Cortec VpCI-415 can provide significant corrosion protection for up to six months, giving you peace of mind that your valuable assets are safeguarded long after they've been cleaned.

Relevant products you may want to consider:

Application & Usage: Getting the Most Out of Cortec VpCI-415

• Can Cortec VpCI-415 be used in everyday workshop cleaning or is it only for industrial settings?

While it's a heavy-duty industrial cleaner, Cortec VpCI-415 is quite versatile and can be adapted for various cleaning needs. Its effectiveness in removing stubborn contaminants makes it suitable for a wide array of applications beyond just large-scale industrial operations, such as cleaning machinery in a busy workshop.

• What's the best way to apply Cortec VpCI-415 for effective cleaning and corrosion protection?

You've got options! Cortec VpCI-415 can be applied using conventional equipment like sprayers, dipping tanks, steam cleaners, and power washers. The key is to ensure good contact with the surfaces you're cleaning and protecting.

• What are the recommended dilution ratios for Cortec VpCI-415 for different cleaning tasks?

For heavy-duty cleaning and corrosion protection, a dilution ratio of 1 part Cortec VpCI-415 to 4 parts water is recommended. For normal cleaning, like parts washing, you can go with 1 part VpCI-415 to 10 parts water. If you're just doing a light cleaning or rinsing, a 1:20 ratio is ideal.

• Can I use Cortec VpCI-415 with hard water without losing effectiveness?

Yes, absolutely! One of the fantastic features of Cortec VpCI-415 is its hard water stability. This means you can use it confidently even if your water supply has a high mineral content, without compromising its cleaning or protective properties.

• Is it necessary to rinse surfaces after using Cortec VpCI-415?

Typically, after cleaning with Cortec VpCI-415, the deposits are emulsified and carried away with water, so a thorough rinse is usually part of the process to ensure all contaminants are removed and the surface is left clean and ready for its protective layer.

Relevant products you may want to consider:

• Can Cortec VpCI-415 be used as a surface preparation before painting or applying other coatings?

Yes, it's an excellent first step in surface preparation! By thoroughly cleaning and degreasing metals and providing flash corrosion protection, Cortec VpCI-415 helps create a clean, prepared surface that's ideal for subsequent painting or coating applications, ensuring better adhesion and longevity.

Specific Use Cases & Problem Solving

• I have a lot of machinery contaminated with oils and greases. How effective is Cortec VpCI-415 for this?

Cortec VpCI-415 is specifically formulated to be a heavy-duty cleaner and degreaser, making it incredibly effective at removing tough deposits like heavy hydrocarbons, greases, and even drawing, stamping, and buffing compounds from machinery.

• Will Cortec VpCI-415 help prevent flash rust after cleaning, especially on bare metals?

Absolutely, that's one of its key benefits! The unique VpCI technology in Cortec VpCI-415 provides immediate flash corrosion protection on freshly cleaned metal surfaces, which is crucial for preventing rust from forming quickly after cleaning.

• Can Cortec VpCI-415 be used to clean aircraft components?

Yes, it can. Cortec VpCI-415 is formulated to meet the stringent requirements for cleaning and corrosion protection of aircraft, making it a trusted solution in the aviation industry.

• My metal parts are coated with temporary protective oils or waxes. Can Cortec VpCI-415 remove these?

Indeed, Cortec VpCI-415 is very effective at removing temporary protective oils or waxes, which is essential for preparing these surfaces for further processing or painting.

Relevant products you may want to consider:

• How does Cortec VpCI-415 handle pitted corrosion?

Cortec VpCI-415 offers exceptional resistance to pitting corrosion, which means it not only cleans effectively but also actively helps to prevent this particularly damaging form of corrosion.

• Is Cortec VpCI-415 suitable for use in dip tanks for batch cleaning?

Yes, it is! Cortec VpCI-415 can be effectively metered into dip tanks, making it a convenient and efficient solution for batch cleaning operations.

• Can this product be used in low-temperature environments?

Cortec VpCI-415 exhibits excellent cleaning action even at low temperatures and its formulation remains stable during freeze-thaw cycles, making it suitable for use in a variety of climate conditions.

Technical & Safety Information

• Does Cortec VpCI-415 produce a lot of foam when used?

Cortec VpCI-415 has a mild foaming characteristic, which aids in its cleaning action without creating an excessive amount of foam that could be difficult to manage.

• What are the storage recommendations for Cortec VpCI-415 to maintain its effectiveness?

To ensure the product retains its optimal performance, it's best to keep the container tightly closed and store it according to the manufacturer's recommendations. The shelf life is typically up to 24 months.

• Is Cortec VpCI-415 non-toxic and safe for workers to handle?

Yes, Cortec VpCI-415 is classified as non-toxic and non-corrosive, making it a safer option for worker handling compared to many traditional industrial cleaners. Always refer to the Safety Data Sheet (SDS) for complete handling guidelines.

• Does Cortec VpCI-415 contain any hazardous air pollutants (HAPS)?

No, it does not. Cortec VpCI-415 is formulated without hazardous air pollutants, contributing to a healthier working environment.

• Is Cortec VpCI-415 flammable?

No, it is non-flammable and non-combustible, which significantly enhances safety during storage, transport, and use.

Relevant products you may want to consider:

Purchasing & Logistics

• What packaging sizes is Cortec VpCI-415 available in from Valdamark Direct?

Valdamark Direct typically offers Cortec VpCI-415 in convenient sizes to suit various needs, including 19-liter pails and 208-liter drums, and it's also available in liquid totes and bulk for larger requirements.

• Is there a specific shelf life for Cortec VpCI-415?

Yes, Cortec VpCI-415 has a shelf life of up to 24 months when stored correctly, ensuring its efficacy over a considerable period.

• Where can I access the technical data sheet (TDS) and safety data sheet (SDS) for Cortec VpCI-415?

You can usually find the technical data sheet (TDS) and safety data sheet (SDS) for Cortec VpCI-415 available for download on product pages from reputable suppliers like Valdamark Direct, often after logging in or signing up.

Comparative & Advanced Questions

• How does Cortec VpCI-415 compare to traditional solvent-based degreasers?

Cortec VpCI-415 stands out by being a water-based, biodegradable alternative to harsh solvent-based degreasers. It offers superior environmental and safety benefits, as it's non-toxic, non-flammable, and free of VOCs, while still delivering powerful cleaning and crucial flash corrosion protection that solvents often lack.

• Can Cortec VpCI-415 replace multiple products in my cleaning and rust prevention process?

Yes, absolutely! Its ability to both clean and provide temporary corrosion protection in one step means you can often consolidate multiple products and processes into a single, efficient solution, saving you time and money.

Relevant products you may want to consider:

• Are there any industry standards or certifications that Cortec VpCI-415 conforms to?

Yes, Cortec VpCI-415 conforms to various industry standards, including MIL-PRF-87937D, and has undergone testing according to ASTM D 2240, ASTM F 483-90, ASTM F 484-93, ASTM F 485-98, ASTM F 502-93 F, ASTM F 519-93 Type 1C, ASTM F 1104-87, and ASTM F 1110-90, highlighting its reliability and performance.

• What are the long-term benefits of integrating Cortec VpCI-415 into my maintenance routine?

Integrating Cortec VpCI-415 into your maintenance routine offers long-term benefits such as reduced material waste due to corrosion, extended equipment lifespan, improved operational efficiency by streamlining cleaning and protection steps, and a safer, more environmentally friendly workplace.