Cortec CorShield® VpCI® 369 19Ltr Pail Drums | MIL– PRF – 16173E (Grades 1 & 2) Oil Based Temporary Coating | For Extreme Corrosion Protection in Aggressive Environments

Cortec CorShield® VpCI® 369 19Ltr Pail Drums | MIL– PRF – 16173E (Grades 1 & 2) Oil Based Temporary Coating | For Extreme Corrosion Protection in Aggressive Environments

Low stock: 8 left

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

19Ltr Pail: Cortec CorShield® VpCI®-369 - Oil-Based, Heavy-Duty Corrosion Inhibitor

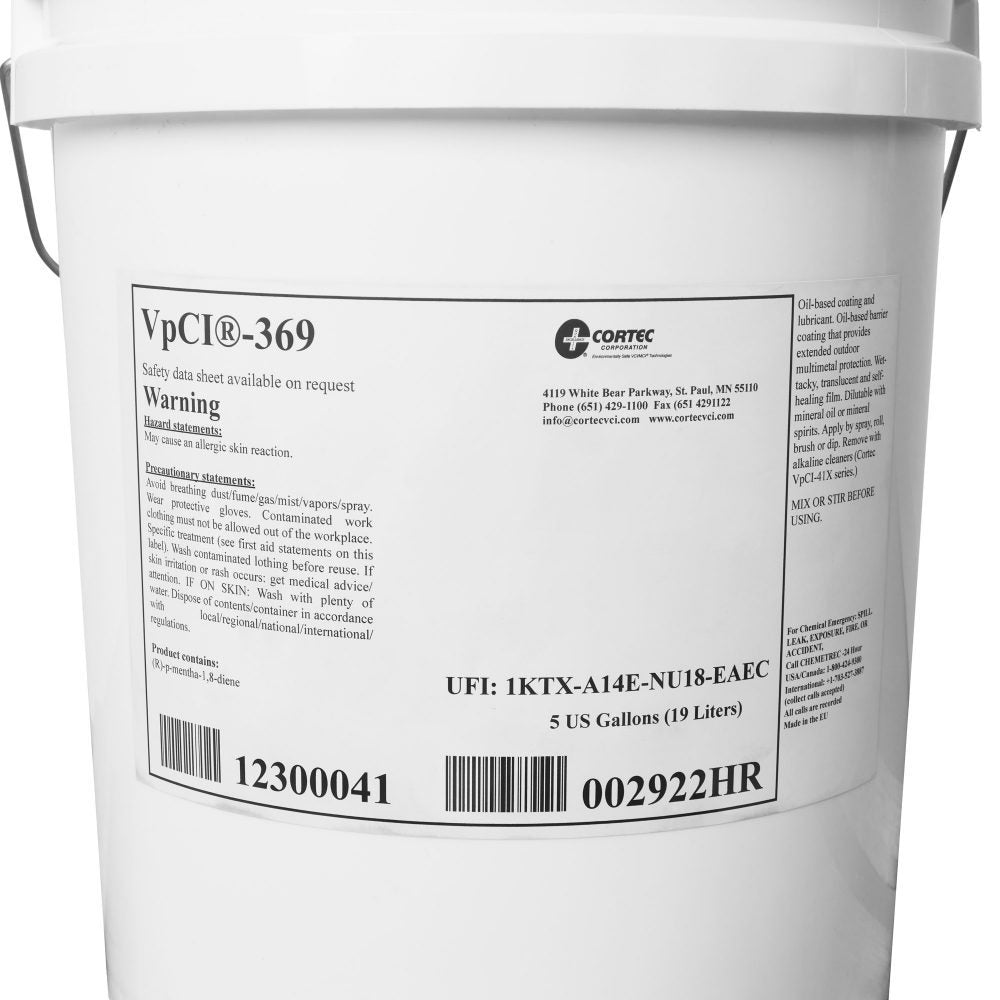

The 19Ltr pail of Cortec CorShield® VpCI®-369 delivers a high-performance, oil-based temporary coating designed to provide robust protection in demanding outdoor and aggressive environments. This formulation meets the requirements of MIL-PRF-16173E (Grade 2), offering a reliable solution for critical asset protection.

Superior Outdoor Corrosion Protection with 19Ltr Pail

VpCI®-369 forms a durable, wet-film protective coating that effectively shields metals from corrosion, even under severe environmental conditions. This product is ideal for exposed, unsheltered applications. The 19Ltr pail allows for efficient application on large surfaces via spray, brush, roller, or dip methods.

Key Features of the 19Ltr VpCI®-369 Pail:

- Heavy-Duty Protection: Designed for harsh outdoor and aggressive conditions.

- Oil-Based Formulation: Provides a durable, wet-film protective coating.

- MIL-PRF-16173E Compliance: Meets Grade 2 standards.

- Multi-Metal Compatibility: Protects various metal types.

- NSN and UFI Codes: NSN 8030-00-244-1295, 244-1297, 244-1298, 01-149-1731. UFI: 1KTX-A14E-NU18-EAEC.

- Bulk Application: 19Ltr pail for large-scale projects.

Application Guidelines (19Ltr Pail):

- Surface Preparation: Ensure surfaces are free from grease, oil, rust treatments, dirt, debris, and fingerprints. SSPC-SP1 is recommended for painted surfaces, and NACE #3/SSPC-SP6 for bare metals.

- Mixing: Agitate VpCI®-369 thoroughly before use.

- Application Methods: Apply via spray, brush, roller, or dip.

- Spray Equipment Calibration:

- Conventional/HVLP: Tip 0.02"-0.11", air pressure 45-55 psi, fluid pressure 10 psi.

- Airless/Air-Assisted: Tip 0.015"-0.035", pressure 1800-2500 psi.

- Post-Application Cleanup: Clean tools and equipment immediately with butyl acetate (wet) or VpCI® 414 alkaline cleaner degreaser.

Packaging and Storage (19Ltr Pail):

- Available in 19Ltr pails.

- Store in original packaging, away from direct sunlight.

- Shelf life: 2 years.

- Store in accordance with dangerous goods regulations (UN1950).

- Please consult the safety data sheet.

Metal Compatibility:

- Various metals (consult product data sheet for specific compatibility).

Typical Applications:

- Protection of metal components in outdoor storage.

- Corrosion prevention during transportation.

- Protection of machinery and equipment exposed to harsh environments.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is Cortec CorShield VPCI-369, and why might I need it?

Cortec CorShield VPCI-369 is an oil-based, temporary coating designed to provide exceptional corrosion protection for metal assets, even in the most demanding outdoor and aggressive environments. You'd typically need it to prevent rust and corrosion on valuable equipment or parts during storage, shipping, or lay-up, ensuring they remain in pristine condition. For related products, you might also be interested in Cortec CorShield VPCI-369 19ltr Pail or VPCI Corrosion Inhibitor Coating.

• How does this product stand out from other corrosion inhibitors on the market?

Cortec CorShield VPCI-369 is distinct because it forms a self-healing and moisture-displacing protective film. This means it actively works to repel moisture and, if the film gets scratched or disrupted, it has the ability to repair itself, offering continuous, robust protection that’s commercially compliant with MIL-PRF-16173E (Grade 2). Learn more about similar products like Cortec VPCI-325 Corrosion Protection Liquid and Cortec CorShield VPCI-368 19ltr Outdoor Corrosion Protection Coating.

• What's the typical shelf life of a 19-liter pail of Cortec CorShield VPCI-369?

When stored correctly in its original packaging, indoors, and away from direct sunlight, a 19-liter pail of Cortec CorShield VPCI-369 has a shelf life of approximately two years. Additional storage solutions can be found at Cortec Ecoline ELP 19ltr Pail Drums.

• Is the Cortec CorShield VPCI-369 suitable for all types of metals?

Yes, this product is highly versatile and effective on a broad range of metals, including silver, cast iron, stainless steel, copper, magnesium, aluminum, and carbon steel, providing multi-metal protection.

• What's the primary purpose of Cortec CorShield VPCI-369 – is it a long-term solution or temporary protection?

Cortec CorShield VPCI-369 is primarily designed as a temporary protective coating. While it offers long-term protection for assets during lay-up or storage (up to 5+ years), it’s meant to be removable when the equipment is ready for use, rather than a permanent paint film.

• Does this product act as a lubricant in addition to being a corrosion inhibitor?

Absolutely! Cortec CorShield VPCI-369 provides excellent lubricity, making it ideal for protecting working and moving parts like gears and shafts, while also acting as a superior corrosion inhibitor. For similar applications, explore Cortec Ecoline ELP Penetrating Lubricant Spray and Cortec CorrLube VPCI Lithium EP Grease.

• Can Cortec CorShield VPCI-369 be used as an additive for oils?

Yes, it's an excellent choice for use as an oil additive, particularly for mothballing, shipping, or long-term storage of parts and equipment. When added in small percentages, it has a minimal impact on the viscosity of the oil. Consider other additives like Cortec VPCI-326 Top Tier Corrosion Inhibitor Oil.

Application & How-To

• What kind of preparation does a surface need before applying Cortec CorShield VPCI-369 for best results?

For optimal adhesion and performance, the surface you're treating should be meticulously clean and free from any greases, oils, rust treatments, dirt, debris, and even fingerprints. For bare metal, a NACE #3/SSPC-SP6 standard is recommended, while for painted surfaces, aim for at least SSPC-SP1. Cleaning products like Cortec VpCI-414 19ltr Cleaner Degreaser and Cortec Ecoline Cleaner Degreaser can be helpful.

• Do I need to mix or agitate the product before applying it from the 19-liter pail?

Yes, agitation is crucial to ensure the VpCI-369 has a consistent, even consistency before application. This can be achieved using a squirrel cage design mixer, a handheld tool, or other similar mixing methods.

• What are the common methods for applying Cortec CorShield VPCI-369 from the 19-liter pail?

You have several flexible options for application: it can be sprayed, rolled, brushed, or even applied by dipping the parts directly into the pail. For spray applications, see products like Cortec CorShield VPCI-369 Outdoor Corrosion Inhibitor Spray.

• When using a spray application, what kind of equipment setup is recommended for Cortec CorShield VPCI-369?

For conventional spraying (HVLP), a tip between 0.02″ – 0.11″ (0.5-2.8 mm) with 45-55 PSI air pressure and 10 PSI fluid pressure is generally recommended. For airless or air-assisted systems, use a 0.015″ – 0.035″ (0.38-0.89mm) tip with pressure between 1800-2500 PSI. Always ensure proper hose dimensions and maintain dual regulation for the pot and spray gun.

• How thick should the film of Cortec CorShield VPCI-369 be for effective protection?

For robust protection, a typical film thickness of 1-2 mils (25-50 microns) is generally recommended, which allows for a theoretical spread rate of 753-1506 sq ft/gallon (18.8-37.6 m2/L).

• Can I apply multiple coats of Cortec CorShield VPCI-369 if I need extra protection in severe conditions?

Yes, for applications where particularly severe conditions are expected, or where extended protection is critical, you can certainly apply multiple coats of Cortec CorShield VPCI-369 to achieve the desired film thickness and enhanced protection.

• What's the best way to clean tools and equipment after using Cortec CorShield VPCI-369?

It's important to clean all your tools and equipment immediately after use while the coating is still wet. Butyl acetate is recommended for this cleanup, and always remember to follow the manufacturer's safety advice for any solvents used.

• How do I remove Cortec CorShield VPCI-369 when the protection is no longer needed?

To remove the VPCI-369 coating, an alkaline cleaner degreaser such as VpCI-414 is recommended. This will effectively break down and remove the oily film, preparing the surface for its next stage of use. Other cleaning options include Cortec VPCI-417 Heavy Duty Cleaner Degreaser.

Application Usages & Scenarios

• Is Cortec CorShield VPCI-369 a good choice for protecting machinery during long-term storage or lay-up?

Absolutely, it's one of the best inhibitors for long-term (5+ years) equipment lay-up and storage, providing excellent protection against corrosion without the need for constantly controlled humidity environments.

• Can this product be used to protect wire rope from rust and wear?

Yes, Cortec CorShield VPCI-369 is specifically listed as a typical application for wire rope, offering both corrosion protection and excellent lubricity to extend its lifespan.

• How effective is Cortec CorShield VPCI-369 for protecting electrical connections and wiring?

This product is highly effective for electrical connections and wiring, providing a protective barrier against corrosion that can compromise conductivity and integrity in various environments. Consider using it alongside Cortec VPCI-238 Electrical Contact Cleaner.

• Would Cortec CorShield VPCI-369 be suitable for protecting automotive parts that are being stored or shipped?

Yes, its ability to protect various metals and its self-healing, moisture-displacing film make it an ideal temporary coating for automotive parts during shipping, storage, or even for mothballing vehicles. For other automotive protection, you might explore Cortec Ecoline 3690 Oil-Based Temporary Coating.

• Can I use Cortec CorShield VPCI-369 for protecting internal engine components or cylinders during storage?

Yes, it is excellent for protecting cylinders and other working/moving parts internally, and it can also be used as an oil additive for mothballing engines or hydraulic systems.

• Is Cortec CorShield VPCI-369 a good solution for preserving stamped or drawn metal parts?

It is indeed, as Cortec CorShield VPCI-369 is recommended as an additive for both stamping and drawing oils, providing corrosion inhibition during metalworking operations.

• How does Cortec CorShield VPCI-369 perform in aggressive outdoor conditions, like marine environments?

This oil-based temporary coating is specifically designed to cope with the most demanding outdoor and aggressive conditions, offering superior protection against the harsh elements found in marine and high-humidity environments. Also check out Cortec Ecoline 3680 Biobased Open Atmosphere Corrosion Inhibitor.

• Can this product protect metal assets that are exposed to temperature extremes?

Cortec CorShield VPCI-369 is temperature stable, with a resistance range from -108°F to 500°F (-78°C to 260°C) once fully cured, making it suitable for a wide range of operating temperatures.

• Is it suitable for protecting industrial equipment that will be sheltered but still exposed to some humidity?

Yes, it’s an excellent choice for sheltered coating applications, offering robust protection to industrial equipment even when it's not fully sealed from the elements but still protected from direct rain and sun.

Technical & Safety Details

• What industry specifications or military standards does Cortec CorShield VPCI-369 meet?

This product fully conforms commercially to MIL-PRF-16173E (Grade 2), and also has several National Stock Numbers (NSNs) associated with it, such as 8030-00-244-1295, 244-1297, 244-1298, and 01-149-1731, indicating its high-performance standards.

• What is the flash point of Cortec CorShield VPCI-369?

The flash point for Cortec CorShield VPCI-369 is 233°F (112°C).

• What is the typical viscosity of Cortec CorShield VPCI-369?

The typical viscosity of Cortec CorShield VPCI-369 ranges from 10,000 to 45,000 cps, which contributes to its ability to form a robust, oily film.

• What are the general safety precautions I should take when handling Cortec CorShield VPCI-369?

It's crucial to follow standard industrial hygiene practices. Ensure good ventilation, wear appropriate personal protective equipment like gloves and eye protection, and refer to the product's Safety Data Sheet (SDS) for comprehensive health and safety information. Avoid exposure to heat, sparks, and open flames.

• How should I store the 19-liter pail of Cortec CorShield VPCI-369 to maintain its quality?

The 19-liter pail should be stored in its original packaging, indoors, away from direct sunlight, and within a temperature range of 40-100°F (4-38°C) to ensure optimal product performance and shelf life.

• Does the product displace moisture, or does the surface need to be perfectly dry before application?

Cortec CorShield VPCI-369 is a moisture-displacing coating, meaning it actively pushes away moisture from the metal surface, which contributes to its superior corrosion protection. However, the surface should still be clean and free from excess water for the best results. For further information on related products, visit VPCI Vapour Phase Corrosion Inhibitors.